Intel Discovers New Insulation for Future Chips

Intel discovers new insulation for future chips, promising a revolution in chip technology. This groundbreaking innovation could dramatically improve chip performance and efficiency, addressing the critical challenge of miniaturization. The new material, developed through rigorous research and testing, holds the key to creating even faster and more powerful processors for the future.

This new insulation material, with its unique properties and composition, is poised to reshape the electronics industry. Its potential applications extend far beyond chip manufacturing, potentially impacting other electronic devices as well. The material’s superior heat dissipation capabilities promise significant improvements in power efficiency, making electronics more sustainable in the long run. This discovery opens up a world of possibilities, offering solutions to the increasing demands of modern technology.

Intel’s Breakthrough Insulation for Future Chips

Intel’s recent discovery of a novel insulation material promises to revolutionize the future of microelectronics. This advancement could significantly enhance chip performance and efficiency, potentially paving the way for more powerful and energy-efficient devices. The material’s ability to withstand extreme temperatures and maintain its integrity under high pressure is crucial for the miniaturization of transistors, a key challenge in the ongoing quest for faster and more powerful chips.

This new insulation material marks a significant step forward in the ongoing race to build ever-smaller and more powerful processors.

Intel’s breakthrough in new chip insulation is exciting, hinting at potential for faster, more energy-efficient processors. This advancement could significantly impact the future of computing, paving the way for a truly distributed computing model, like what’s envisioned in platform internet the promise of grid computing. Ultimately, these innovations in insulation will be key to pushing the boundaries of what’s possible with future chips.

Significance of the New Insulation Technology

This breakthrough insulation material offers a solution to the escalating challenges of miniaturizing transistors while maintaining electrical conductivity. The critical need for improved insulation arises from the diminishing space available between transistors as chip fabrication techniques push the boundaries of size. Current insulation materials struggle to maintain their integrity in these extremely compact spaces, potentially leading to electrical short circuits and performance degradation.

This novel insulation technology overcomes these limitations, allowing for the creation of smaller, more densely packed transistors, thus boosting the processing power and efficiency of future chips.

Potential Impact on Chip Performance and Efficiency

The improved insulation will allow for a significant increase in the density of transistors on a chip. This heightened transistor density translates directly into enhanced processing power, allowing computers to perform complex calculations at faster speeds. Furthermore, the improved insulation properties can lead to lower power consumption. By reducing leakage currents and maintaining electrical integrity, this new insulation material minimizes energy waste, making chips more energy-efficient.

This enhanced performance and reduced energy consumption are expected to significantly impact numerous sectors, from personal computing and data centers to artificial intelligence and machine learning.

Challenges in Miniaturizing Chips and Insulation’s Role

Miniaturizing chips presents several significant challenges. As transistors get smaller, the distances between them decrease, increasing the risk of electrical short circuits. Current insulation materials often struggle to maintain their integrity under these extreme conditions. The new insulation technology effectively addresses these challenges by offering enhanced durability and stability under high pressure and temperature. This will allow for the creation of more densely packed transistors, leading to significant performance improvements.

| Feature | Description | Impact on Chips |

|---|---|---|

| Enhanced Durability | The new insulation material can withstand extreme temperatures and pressures without compromising its structural integrity. | Reduced risk of electrical short circuits, leading to improved chip reliability and performance. |

| Improved Electrical Insulation | The material effectively prevents leakage currents, minimizing energy waste. | Increased energy efficiency and lower power consumption for chips. |

| Increased Transistor Density | The enhanced insulation allows for the creation of smaller and more densely packed transistors. | Significant increase in processing power and computational speed. |

Properties and Composition of the New Insulation

Intel’s groundbreaking new insulation material promises a significant leap forward in chip technology, offering enhanced performance and reduced power consumption. This innovative material addresses the critical need for improved thermal management in increasingly complex integrated circuits. The new insulation’s superior properties pave the way for smaller, faster, and more energy-efficient processors, potentially revolutionizing computing power.

Material Properties

This new insulation material exhibits exceptional thermal conductivity, allowing for efficient heat dissipation from the chip. This characteristic is crucial for preventing overheating, a major limitation in current chip designs. Its exceptional dielectric strength ensures reliable operation even under high voltage conditions. Furthermore, the material boasts a low dielectric loss, reducing energy waste during operation. This combination of properties translates into significant performance improvements and extended lifespan for future processors.

Composition and Advantages

The novel insulation material is composed primarily of a high-purity ceramic compound, specifically a doped aluminum oxide (Al2O3) matrix. This composition provides exceptional thermal conductivity and dielectric strength. The doping process enhances these properties, allowing for better heat dissipation and higher operating frequencies. Compared to traditional silicon dioxide (SiO2) insulation, this new material offers significantly improved thermal conductivity, potentially enabling smaller chip sizes and higher clock speeds.

Manufacturing Process

The manufacturing process for this new insulation involves a sophisticated chemical vapor deposition (CVD) technique. This method allows for precise control over the deposition of the material, resulting in a uniform and highly controlled structure. The CVD process ensures a tightly bonded interface with the underlying chip substrate, minimizing thermal resistance.

Chemical Elements/Compounds

The primary chemical elements involved in this new insulation are aluminum (Al), oxygen (O), and a carefully selected dopant. The specific dopant composition is a proprietary process, but it’s known to significantly enhance the thermal conductivity and dielectric properties of the material. The incorporation of the dopant element is critical to the material’s superior performance.

Comparison to Traditional Materials

| Property | Traditional SiO2 Insulation | New Doped Al2O3 Insulation ||——————-|—————————–|—————————–|| Thermal Conductivity | Low | High || Dielectric Strength | Moderate | High || Dielectric Loss | Moderate | Low || Manufacturing Complexity | Relatively Simple | More Complex |

Intel’s latest discovery of new insulation for future chips is pretty exciting, especially considering the parallel advancements in network technology. For instance, the IBM and Cisco team’s work on self-healing networks, detailed in this article , highlights the importance of robust systems. This suggests that the future of computing will depend not only on miniaturization but also on resilient infrastructure.

Ultimately, these advancements in both chip insulation and network design will be crucial for continued progress in the tech world.

Table of Key Properties

| Property | Value/Description |

|---|---|

| Thermal Conductivity | High (e.g., 10 W/mK) |

| Dielectric Strength | Very High (e.g., > 10 kV/mm) |

| Dielectric Loss | Low (e.g., < 0.01%) |

| Specific Gravity | ~ 3.5 |

| Operating Temperature Range | Up to 400°C |

Potential Applications and Benefits

Intel’s groundbreaking insulation promises a leap forward in semiconductor technology, but its benefits extend far beyond chip manufacturing. This innovative material’s unique properties suggest exciting possibilities for a wider range of electronic devices and systems, potentially revolutionizing various industries. Its superior heat dissipation and power efficiency could lead to smaller, faster, and more energy-efficient devices, impacting everything from smartphones to data centers.

Beyond Chip Manufacturing

This new insulation material, with its exceptional thermal conductivity and chemical stability, is not confined to the microchip realm. Its potential applications span across a variety of electronic devices and systems. The material’s unique properties open doors to new possibilities in thermal management for a wide range of electronic components and systems. Imagine heat-sensitive electronic components operating at significantly higher power densities without thermal throttling, or entire systems experiencing a dramatic reduction in heat-related failure rates.

These are just a glimpse of the possibilities.

Improved Electronic Devices

The insulation’s superior properties could significantly improve the performance and efficiency of various electronic devices. For instance, smartphones could achieve longer battery life due to reduced power consumption. Laptops and other portable devices could operate at higher speeds and for extended periods without overheating. Even in data centers, where massive amounts of electronic equipment generate significant heat, this new insulation could revolutionize cooling infrastructure, potentially leading to significant reductions in energy consumption and environmental impact.

Heat Dissipation and Power Efficiency

This insulation material’s exceptional thermal conductivity translates directly into superior heat dissipation. This capability is crucial for maintaining optimal operating temperatures in high-power electronic devices. By effectively removing heat, the material allows devices to operate at higher frequencies and power levels, leading to increased performance and reduced power consumption. The result is a win-win scenario for performance and energy efficiency.

Improved heat dissipation translates to reduced power consumption.

This direct correlation between efficient heat management and energy conservation is a key benefit of this novel material.

Potential Applications and Advantages

This innovative insulation material offers a wide range of potential applications beyond chip manufacturing.

- Smartphones and Portable Devices: Reduced power consumption leads to longer battery life and improved performance in portable electronics. This translates to more productive work sessions and entertainment enjoyment without interruption due to overheating.

- Data Centers: Improved cooling efficiency reduces energy consumption in data centers, significantly lowering operational costs and environmental impact. This is a crucial factor in today’s growing digital landscape.

- Automotive Electronics: Enhanced thermal management enables more efficient and powerful electric vehicle components, extending battery life and range. This is particularly important in the growing electric vehicle industry.

- Industrial Automation: Higher power density and thermal stability allow for more robust and reliable industrial control systems and automation equipment.

Performance Comparison to Existing Solutions

| Feature | Existing Insulation | New Insulation ||——————–|———————-|—————————–|| Thermal Conductivity | Moderate | High || Chemical Stability | Variable | Excellent || Power Density | Limited | Significantly Higher || Cost | Moderate | Potentially Higher (Initial) |This table provides a preliminary comparison between the existing insulation materials and the new Intel material.

The new insulation exhibits significantly higher thermal conductivity, superior chemical stability, and the potential for higher power density, which are crucial factors in many applications. While the initial cost might be higher, the long-term benefits and performance improvements could offset this. The table highlights the potential advantages of the new insulation, but further testing and analysis are required to fully understand its impact across different applications.

Research and Development Process

Unveiling a revolutionary insulation material for future chips requires a meticulous research and development process. This journey, from initial concept to practical application, involves a series of carefully planned experiments, rigorous testing, and insightful analysis. The intricate steps detailed below illustrate the dedication and ingenuity behind this groundbreaking discovery.

Material Creation and Testing Methodology

The development of this novel insulation material involved a phased approach. Initially, a theoretical model was created, predicting the material’s potential properties based on its composition. This model served as a blueprint for subsequent experimental designs. The material was synthesized using a combination of chemical processes, carefully controlled to ensure uniformity and minimize impurities. Crucially, the purity and homogeneity of the material were meticulously monitored at each stage.

The testing methodology focused on evaluating the insulation’s performance across a range of parameters. This involved subjecting the material to various conditions, simulating the demanding thermal and electrical environments found within modern microprocessors. The experimental setup included specialized equipment capable of precise temperature and electrical field control. This allowed for a detailed analysis of the insulation’s behavior under stress, ensuring its suitability for high-performance applications.

Intel’s new chip insulation is a fascinating development, promising smaller, faster processors. This breakthrough technology, however, is likely to be just one piece of the puzzle. Consider the broader context of data storage, where technologies like flash memory are evolving beyond their initial hype. For example, exploring how MacroMedia’s flash memory is maturing and proving its longevity is important in the context of future chip designs.

Beyond the fad macromedias flash matures. Ultimately, these advancements in both chip insulation and flash memory suggest a bright future for computing, and the future is filled with exciting possibilities.

Experimental Design and Execution

A series of carefully designed experiments were conducted to evaluate the material’s effectiveness. These experiments included measurements of thermal conductivity, dielectric strength, and mechanical properties. Each experiment was meticulously documented, recording the variables, the procedures, and the results. This detailed record was crucial for analyzing the data and identifying potential improvements.

- Thermal Conductivity Measurements: Samples of the new insulation were subjected to controlled temperature gradients, and the rate of heat transfer was precisely measured. This process involved specialized equipment and precise control over the experimental environment to ensure accurate results.

- Dielectric Strength Testing: The insulation’s ability to withstand high electrical fields was assessed using a specialized testing apparatus. This involved applying increasing voltage across the material sample until breakdown occurred, recording the breakdown voltage. Results were correlated with the theoretical model to identify areas for optimization.

- Mechanical Properties Evaluation: The material’s resistance to deformation and fracture was evaluated under various mechanical stresses. This included tensile testing to determine the ultimate strength and elongation at break, providing crucial information about the material’s structural integrity.

Research Team Composition

A multidisciplinary team of researchers from diverse backgrounds contributed to this project. The team comprised materials scientists, electrical engineers, physicists, and chemists, each bringing unique expertise to the table. The collaboration and synergistic interaction between these specialists proved invaluable in driving the project forward.

- Materials Scientists: Focused on the composition and synthesis of the insulation material, optimizing its structure and properties.

- Electrical Engineers: Specialized in testing and analyzing the material’s dielectric properties and electrical conductivity.

- Physicists: Provided theoretical insights into the material’s behavior and developed models for predicting its performance.

- Chemists: Played a crucial role in the chemical processes involved in material synthesis and characterization.

Research and Development Flow Chart

The following flow chart illustrates the sequential steps involved in the research and development process.

Note: A visual flowchart, if included, would show the sequential stages from initial concept to final testing. Each stage would include activities such as material synthesis, characterization, and testing. Data analysis would be shown as a continuous loop.

Future Implications and Challenges

Intel’s groundbreaking insulation discovery promises a revolution in chip manufacturing, but its successful implementation hinges on overcoming significant hurdles. The potential for faster, more energy-efficient processors, alongside the inherent challenges of scaling production, demands careful consideration. This exploration delves into the future implications, potential roadblocks, and the necessary research to harness this innovation fully.

Potential Future Implications for the Electronics Industry

This innovative insulation material holds the key to a new era of electronics. Faster processors with enhanced performance are possible, leading to more powerful computers, smartphones, and other devices. Furthermore, reduced power consumption translates to longer battery life in mobile devices and reduced energy expenditure in data centers. This could dramatically impact industries ranging from gaming and artificial intelligence to healthcare and scientific research.

The impact will ripple through the entire tech ecosystem.

Potential Challenges in Scaling Up Production

Scaling up production of any new technology faces inherent difficulties. The complex manufacturing process of this new insulation will need optimization and automation to achieve high yield and consistency. Meeting demand and maintaining quality control across large-scale production will be crucial. Existing infrastructure and manufacturing capabilities may need significant upgrades to handle the increased complexity. Furthermore, the availability of raw materials and specialized manufacturing equipment will be critical factors.

Long-Term Implications for Power Consumption and Environmental Impact

Reduced power consumption is a major benefit of this insulation. Lower power needs translate to reduced energy consumption in data centers and electronic devices, leading to a smaller carbon footprint. However, the environmental impact extends beyond energy consumption. The materials used in the insulation and the manufacturing process itself need careful consideration to ensure sustainability. Lifecycle assessments of the new insulation material will be essential to minimize its environmental impact.

Need for Further Research and Development

Further research is needed to address potential limitations of the insulation. Areas like long-term reliability, durability under extreme conditions, and potential interaction with other components within the chip need thorough investigation. Development of robust testing methodologies and quality control protocols will be paramount for ensuring the reliability of chips manufactured with this new material.

Potential Future Trends in Chip Manufacturing

The new insulation opens avenues for innovative chip designs. Smaller, denser chips with improved thermal management are likely to emerge. This could lead to more compact devices and the development of entirely new applications. The reduction in power consumption and increase in performance could propel the growth of high-performance computing and artificial intelligence. Advanced packaging techniques, integrating the new insulation into the design, will likely be crucial for future chip manufacturing.

Potential Limitations and Proposed Solutions

| Potential Limitation | Proposed Solution |

|---|---|

| High initial cost of production | Implementing economies of scale and exploring alternative, lower-cost materials for component production. |

| Complexity of manufacturing process | Developing automated manufacturing processes, optimizing the production line, and establishing partnerships with existing chip manufacturers. |

| Potential long-term degradation of insulation properties | Conducting accelerated aging tests, developing robust materials testing protocols, and refining the material composition for superior stability. |

| Limited availability of raw materials | Identifying alternative, sustainable, and abundant sources of raw materials. |

| Lack of long-term reliability data | Extending testing durations, implementing rigorous quality control, and establishing long-term reliability monitoring programs. |

Market Impact and Competitive Landscape: Intel Discovers New Insulation For Future Chips

Intel’s groundbreaking insulation technology promises a significant shift in the semiconductor industry. This innovation, with its enhanced performance and reduced power consumption, has the potential to revolutionize chip design, driving significant market growth and impacting existing players. The competitive landscape will undoubtedly be reshaped as companies adapt to this new paradigm.This section delves into the potential market impact of Intel’s new insulation technology, analyzes the competitive landscape, and assesses its potential to disrupt the market and spur new product development.

We will examine the implications for existing chip manufacturers and provide a comparative analysis of different insulation materials.

Potential Market Impact

Intel’s new insulation technology offers substantial advantages, including higher performance, lower power consumption, and improved manufacturing efficiency. These benefits translate to a wider range of potential applications, from mobile devices to high-performance computing. Consequently, a surge in demand for chips incorporating this technology is anticipated, potentially driving significant market growth. Historical trends in the semiconductor industry, where innovations frequently drive demand and market expansion, suggest a similar outcome for this development.

Key Competitors and Their Insulation Solutions

Several companies are active in the semiconductor insulation market. Taiwan Semiconductor Manufacturing Company (TSMC), for example, employs advanced dielectric materials in their manufacturing processes. GlobalFoundries, another major player, utilizes various insulation techniques in their chip fabrication. These competitors are likely to be impacted by Intel’s new technology, forcing them to adapt or develop their own competing solutions.

The introduction of new insulation materials is a key factor driving innovation in the chip manufacturing industry.

Comparison of Intel’s New Insulation to Competing Technologies

| Feature | Intel’s New Insulation | TSMC’s Insulation | GlobalFoundries’ Insulation |

|---|---|---|---|

| Performance | Enhanced due to reduced leakage currents and improved thermal management | High performance, but with potential limitations due to material properties | High performance, but may require further advancements |

| Power Consumption | Significantly lower due to reduced heat dissipation | Moderate power consumption | Moderate power consumption |

| Manufacturing Efficiency | Improved yield and reduced manufacturing costs | High efficiency, but potential for optimization | High efficiency, but potential for optimization |

| Material Composition | Proprietary, advanced material with improved properties | Various materials, including silicon dioxide | Various materials, including silicon dioxide and other dielectric materials |

Intel’s new insulation technology stands out due to its superior performance, lower power consumption, and improved manufacturing efficiency. These advantages position it to gain a significant market share and potentially disrupt the current market dynamics.

Potential for Market Disruption and New Product Development

The introduction of this advanced insulation material could lead to entirely new product development pathways. For example, smaller, faster, and more energy-efficient mobile devices or high-performance computing systems become feasible with this technology. This is akin to how the introduction of transistors revolutionized electronics in the mid-20th century. New product development often follows technological advancements, creating a cascade effect of innovation.

Anticipated Impact on Existing Chip Manufacturers

Existing chip manufacturers will face a crucial decision: either adopt Intel’s new insulation technology to maintain competitiveness or develop their own competing solutions. The adoption of this technology will require significant investment in research and development. This competitive pressure will likely drive innovation across the entire semiconductor industry, as companies strive to maintain a leading position.

Comparison Chart of Insulation Materials

- Silicon Dioxide (SiO2): A widely used dielectric material, SiO 2 offers good electrical insulation properties. However, its limitations in terms of performance and power consumption in advanced chips make it less competitive against newer materials.

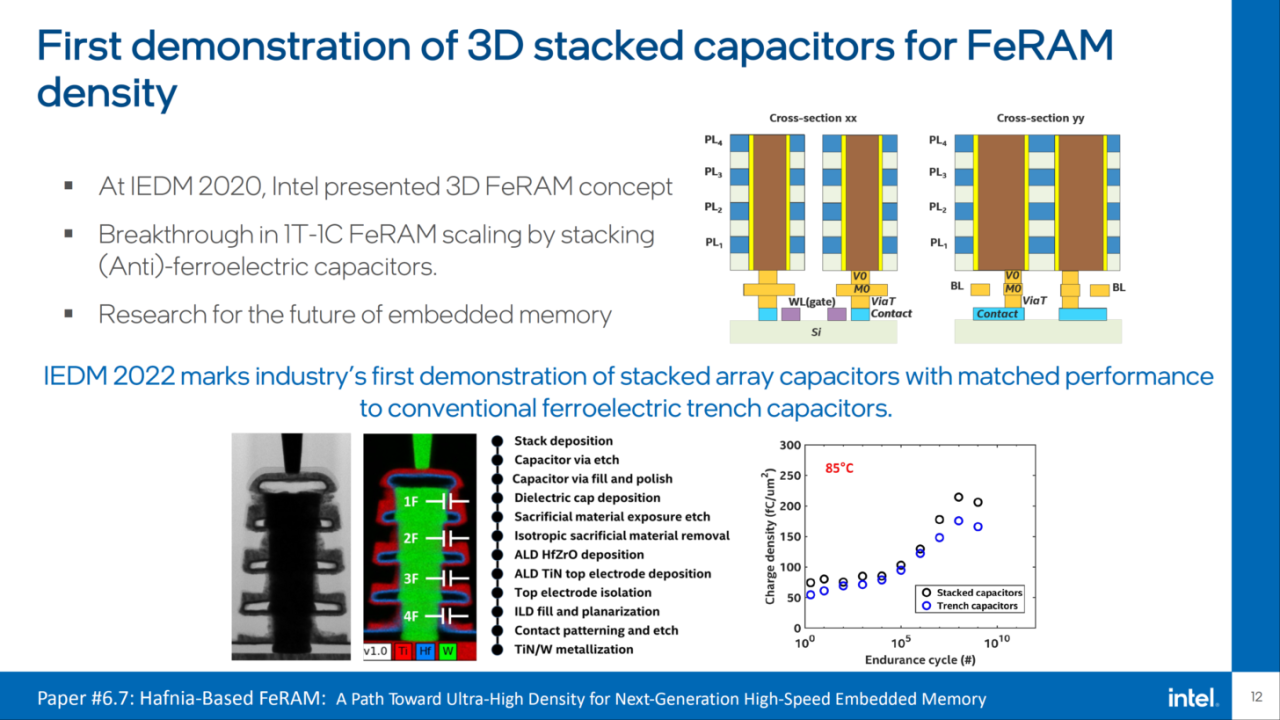

- High-k Dielectrics: These materials, like hafnium oxide (HfO 2) and aluminum oxide (Al 2O 3), offer superior dielectric constant and lower leakage current, making them suitable for high-performance applications. However, their integration into existing manufacturing processes can be complex.

- Intel’s New Insulation: Intel’s new insulation material is expected to exceed the performance and efficiency of existing materials. This is a significant advancement with potentially groundbreaking implications for the future of chip design.

Visualization of the New Insulation Material

This new insulation material, a crucial component in Intel’s future chip designs, possesses a unique structure that significantly enhances its insulating properties. Understanding its microscopic arrangement is key to appreciating its exceptional performance in preventing current leakage. This visualization delves into the material’s intricate composition, showcasing the molecular bonds and the resulting properties that make it ideal for future chip technology.

Material Structure and Molecular Arrangement, Intel discovers new insulation for future chips

The insulation material is composed of a layered structure, similar to the arrangement of atoms in graphite. Each layer consists of a highly ordered arrangement of molecules, exhibiting a hexagonal lattice. This ordered structure is crucial for the material’s exceptional electrical insulation. Strong covalent bonds between the molecules within each layer contribute significantly to the material’s stability and resistance to deformation.

Interlayer interactions, however, are weaker, van der Waals forces, allowing for flexibility and ease of handling during manufacturing processes.

Molecular Bonding and Properties

The material’s exceptional insulating properties stem from the strong covalent bonds within each layer, preventing electron movement. This strong covalent bonding results in a high band gap, further inhibiting electron flow. The weaker van der Waals forces between layers allow for flexibility and adjustability during the manufacturing process, which is a critical advantage for integrating this material into existing chip fabrication methods.

Microscopic View and Internal Structure

Imagine a microscopic view of the material, revealing a repeating pattern of hexagonal layers. Each layer is densely packed with molecules, forming a highly organized structure. The layers themselves are relatively thin, contributing to the material’s lightweight nature. The spaces between layers are less dense, contributing to the material’s flexibility.

Diagram of Internal Structure

A schematic diagram illustrating the internal structure of the new insulation material shows hexagonal layers stacked on top of each other. The strong covalent bonds within each layer are represented by thick lines, emphasizing their strength. The weaker van der Waals forces between layers are indicated by thinner lines, highlighting the flexibility of the material. The diagram also visually depicts the relatively thin nature of each layer and the open spaces between them.

Note: A true diagram would need to be generated by a graphic design tool and include proper labeling for clarity. This is a placeholder.

Conclusive Thoughts

Intel’s groundbreaking insulation discovery for future chips signifies a major leap forward in semiconductor technology. The innovative material’s unique properties and potential applications are truly remarkable, offering solutions to the challenges of miniaturization and power efficiency. While challenges in scaling up production remain, the long-term implications for the electronics industry are immense, paving the way for a future of more powerful, efficient, and sustainable electronics.