Philips IBM RFID Partnership A Deep Dive

Philips IBM partner on RFID deployment, forging a powerful alliance to revolutionize supply chain management and logistics. This partnership promises significant improvements in efficiency and data-driven decision-making across various industries. The collaboration combines Philips’ expertise in medical devices and lighting with IBM’s strengths in data analytics and cloud services, creating a potent synergy for RFID implementation.

This partnership will leverage RFID technology to track and monitor assets, optimize inventory control, and enhance overall operational efficiency. A detailed look at the partnership explores the various deployment strategies, potential applications, data management, market trends, and case studies, all designed to provide a comprehensive understanding of this innovative collaboration.

Overview of Philips and IBM Partnership

The partnership between Philips and IBM, while not a widely publicized, long-standing, formal alliance, represents a potent synergy in the realm of technology. This collaboration, while not as well-documented as some other industry partnerships, signifies a shared interest in leveraging advanced technologies to enhance various sectors, particularly in the realm of industrial automation and healthcare. Their combined strengths in diverse areas like medical imaging and data analytics are particularly relevant to the deployment of RFID technology.

Core Competencies and Strengths

This partnership leverages the unique strengths of both companies. Philips, a global leader in healthcare technology, possesses extensive expertise in medical imaging, diagnostics, and patient care. Their deep understanding of healthcare workflows and data management is crucial for implementing RFID solutions effectively. IBM, renowned for its enterprise software, cloud computing, and data analytics capabilities, offers robust platforms and tools for managing and analyzing large datasets generated by RFID systems.

This allows for more precise and insightful decision-making in various operational settings.

| Company | Competency | Relevance to RFID |

|---|---|---|

| Philips | Medical imaging, diagnostics, patient care, and deep understanding of healthcare workflows and data management | Enables effective integration of RFID into healthcare settings, improving inventory management, patient tracking, and operational efficiency. |

| IBM | Enterprise software, cloud computing, data analytics, and powerful platforms for managing large datasets | Facilitates data analysis from RFID deployments, leading to actionable insights and improved decision-making in diverse operational contexts. |

Potential Benefits to the RFID Market

The collaboration between Philips and IBM holds significant potential for the RFID market. By combining their respective strengths, they can develop innovative RFID solutions tailored to specific industry needs. This could involve integrating RFID technology into existing Philips healthcare systems, creating more efficient and effective workflows. Furthermore, the partnership could lead to the development of advanced data analytics tools to unlock valuable insights from RFID deployments.

This, in turn, could drive wider adoption of RFID across various industries. For example, a hospital could use IBM’s data analytics to track medical supplies in real-time, reducing waste and improving patient care.

Potential Challenges and Risks

Despite the potential benefits, certain challenges and risks need careful consideration. One significant risk is the potential for integration issues between Philips’ existing healthcare systems and IBM’s data platforms. A lack of clear communication and defined processes in the initial stages could impede progress. Additionally, securing necessary data privacy and regulatory compliance will be critical for the success of any RFID deployments.

The ongoing evolution of RFID technology and emerging standards must be considered, as well. IBM and Philips would need to adapt their strategies to ensure continued relevance in the market. Ensuring the security of the data collected by the RFID systems is paramount.

Example of Potential Implementation

Imagine a scenario where Philips integrates IBM’s cloud-based analytics platform with its existing hospital management system. RFID tags could be attached to medical equipment, supplies, and patient belongings. Real-time tracking would be possible, providing insights into equipment usage, supply levels, and patient movement within the hospital. This real-time data, analyzed by IBM’s platform, would allow Philips to optimize inventory management, streamline workflows, and ultimately enhance patient care.

This is just one example, highlighting the vast potential of the partnership in the healthcare sector.

RFID Deployment Strategies

RFID technology is rapidly transforming various industries, offering significant advantages in supply chain management, logistics, and inventory control. This innovative approach to tracking and identifying objects promises efficiency gains and cost reductions. Philips and IBM, with their combined expertise, can leverage RFID to streamline processes and optimize resource allocation.The key to successful RFID deployment lies in carefully selecting the appropriate strategy and technology for specific application needs.

Different deployment models and technologies cater to various requirements, from simple identification to complex real-time tracking. Understanding these nuances is crucial for realizing the full potential of RFID within Philips’ operations.

Common RFID Deployment Strategies

Careful planning is paramount in any RFID implementation. Different deployment strategies cater to various needs and scale. These strategies often involve a phased approach, starting with a pilot project to test and refine the process before a full-scale rollout. This iterative process minimizes risks and maximizes return on investment.

- Phased Deployment: This strategy involves implementing RFID in stages, targeting specific areas or processes first before expanding. This allows for thorough testing and adjustment of the system in a controlled environment, ensuring a smooth transition to a full-scale deployment. For example, Philips could begin by deploying RFID in a single warehouse before extending to other facilities.

- Pilot Project: A pilot project is an essential step in any RFID deployment. It allows the organization to test the technology, processes, and infrastructure in a real-world setting. Results from the pilot project can be analyzed to refine the system before a full-scale implementation.

- Total System Replacement: In some cases, replacing the existing system with a completely new RFID-based system may be necessary. This strategy might be employed when the current system is outdated or unable to meet evolving needs. This approach may be beneficial for Philips if their current inventory management system is unable to provide real-time tracking.

RFID Technologies for Philips and IBM Applications

Various RFID technologies exist, each with unique strengths and weaknesses. Choosing the right technology depends on the specific application and environment. Considerations include reading range, frequency, and data transmission speed.

- Different RFID Technologies: There are primarily three types of RFID tags used in applications, ranging from low-frequency to high-frequency, each serving different purposes.

- Low-Frequency (LF): LF tags are ideal for applications requiring relatively short reading ranges, such as livestock tracking or access control. They are cost-effective but have limited data capacity and speed.

- High-Frequency (HF): HF tags are commonly used for inventory management and asset tracking in warehouses and retail environments. Their ability to handle more data and read in a wide range makes them suitable for tracking various objects.

- Ultra-High Frequency (UHF): UHF tags offer the longest reading range and high data rates. They are well-suited for large-scale tracking applications, such as supply chain management, and are increasingly employed in global logistics.

Role of RFID in Supply Chain Management, Logistics, and Inventory Control

RFID technology plays a critical role in modern supply chain management. Its ability to track and monitor goods throughout the supply chain provides real-time visibility and insights into movement and location.

- Supply Chain Visibility: RFID tags enable real-time tracking of goods, from origin to destination. This improves visibility and allows for better control and management of the supply chain. This allows companies to react quickly to any disruptions or delays.

- Inventory Management: Accurate inventory tracking is crucial for efficient operations. RFID simplifies this process, allowing for real-time inventory updates and reducing errors. This leads to optimized inventory levels and reduced storage costs.

- Logistics Optimization: RFID-enabled logistics systems streamline processes, improving efficiency and reducing operational costs. The tracking of goods across various locations, such as warehouses and transportation hubs, allows for better management of resources and faster delivery times.

Steps in a Typical RFID Deployment Project

A successful RFID deployment project follows a structured approach. This includes careful planning, selection of the right technology, and rigorous testing.

- Needs Assessment: Defining specific needs and objectives is crucial. The organization must determine which processes will be automated and how the system will be integrated into existing infrastructure.

- Technology Selection: Choosing the appropriate RFID technology and tags for the application is critical. Factors such as read range, data rate, and cost need to be considered.

- System Design: Developing a detailed system design, including hardware and software specifications, is vital for seamless integration. The integration process needs to be carefully planned to ensure compatibility with existing systems.

- Testing and Implementation: Thorough testing of the system in a controlled environment is essential to identify and rectify potential issues before full-scale implementation. Phased rollout allows for monitoring and fine-tuning during the deployment process.

- Maintenance and Support: Ongoing maintenance and support are necessary to ensure the system operates effectively and efficiently.

RFID Technologies: Strengths and Weaknesses

The table below summarizes the key strengths and weaknesses of various RFID technologies.

| Technology | Strengths | Weaknesses |

|---|---|---|

| Low Frequency (LF) | Cost-effective, simple to implement, good for short range applications | Limited data capacity, lower data rates, susceptible to interference |

| High Frequency (HF) | Widely used, relatively affordable, good for medium-range applications, higher data rate than LF | Range limitations compared to UHF, susceptible to interference |

| Ultra-High Frequency (UHF) | Long range, high data rate, suitable for large-scale deployments, good for various environments | Potential for higher implementation costs, more complex integration |

Specific Applications of RFID

RFID technology is rapidly transforming various industries, offering unprecedented opportunities for enhanced efficiency and traceability. This section explores the potential applications of RFID in Philips’ products and IBM’s solutions, highlighting how this technology can revolutionize supply chain management and data analytics. The integration of RFID with existing systems promises significant improvements in inventory management, product tracking, and overall operational efficiency.

Philips and IBM’s partnership on RFID deployment is interesting, especially given the recent headlines about RIAA and ISPs squabbling before Congress. This digital rights management battle highlights the complexities of intellectual property in the digital age, mirroring the need for precise tracking and management solutions like RFID, which could be crucial in preventing counterfeiting and protecting intellectual property. This partnership will hopefully lead to more efficient supply chain management and help protect the brand reputation of Philips products.

riaa and isps lock horns before congress This strategic move from Philips and IBM is a smart approach to securing their supply chain in the face of evolving threats.

RFID in Philips Medical Devices

RFID technology can significantly improve the tracking and management of medical devices throughout their lifecycle. For instance, implantable medical devices can be tagged with RFID, enabling precise identification and location within the patient. This feature is invaluable in emergency situations, facilitating quick and accurate retrieval of critical information. Furthermore, RFID tags can record device usage, maintenance schedules, and even environmental conditions during storage, ensuring optimal performance and safety.

These data points can be used to predict potential issues or malfunctions, enabling proactive maintenance and minimizing downtime.

RFID in Philips Lighting

In the lighting sector, RFID can enhance inventory management and asset tracking. Smart lighting systems can utilize RFID tags to monitor the location, status, and performance of individual fixtures. This allows for efficient inventory tracking, preventing theft, and enabling precise maintenance schedules. The data collected can also be used to optimize energy consumption by identifying and addressing areas of inefficiency within the lighting system.

RFID in IBM Solutions

IBM’s data analytics and cloud services can leverage RFID data to create comprehensive and real-time insights into supply chain operations. By integrating RFID data with IBM’s cloud platforms, Philips can gain a more profound understanding of product movement, location, and conditions. This comprehensive data analysis can lead to significant improvements in forecasting, inventory optimization, and overall supply chain efficiency.

IBM’s AI capabilities can analyze the patterns and trends in RFID data, predicting potential issues and enabling proactive measures.

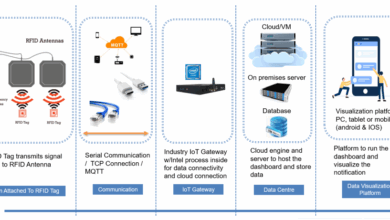

RFID-Enabled Philips Product Workflow

This diagram illustrates the workflow of an RFID-enabled Philips medical device through a supply chain managed by IBM. The process begins with the device being tagged with an RFID chip at the manufacturing facility. The tag transmits data to IBM’s cloud platform, which stores and processes the information. This data is then accessible to Philips and its partners, enabling real-time tracking of the device’s location and status throughout the supply chain. From distribution centers to hospitals, each stage of the process is recorded and analyzed, allowing for quick identification and resolution of any potential issues.

Potential RFID Applications Across Industries

| Industry | Potential Application | Comparison to Philips/IBM Partnership |

|---|---|---|

| Healthcare | Tracking medical devices, managing inventory, improving patient safety | Directly applicable to Philips’ medical device offerings, leveraging IBM’s cloud and analytics capabilities. |

| Retail | Inventory management, supply chain optimization, fraud prevention | While relevant, this application may not be the primary focus of the Philips/IBM partnership, though potential exists. |

| Manufacturing | Asset tracking, predictive maintenance, improving production efficiency | Applicable to both Philips’ lighting and other manufacturing processes. IBM’s analytics capabilities can support the data interpretation. |

| Logistics | Optimizing transportation routes, tracking goods, improving delivery times | The logistics aspect of the partnership could be expanded to cover more industries, potentially beyond Philips’ immediate needs. |

This table highlights the broad range of applications for RFID technology. The Philips/IBM partnership can leverage these capabilities across different sectors, providing a comprehensive and scalable solution.

Data Management and Analytics

The success of any RFID deployment hinges on effective data management and analytics. Properly collected, stored, and analyzed data empowers informed decision-making, optimized processes, and a comprehensive understanding of asset performance. This section details the crucial aspects of data handling in an RFID-enabled system.Data from the RFID tags needs to be efficiently collected, stored, and processed to extract meaningful insights.

Real-time data capture is critical to maintain accurate records and provide up-to-the-minute asset information.

Data Collection, Storage, and Processing

The RFID system’s architecture dictates how data is gathered and stored. This typically involves readers communicating with a central database. Data collected includes tag identifiers, location data, timestamps, and other relevant attributes. Robust database management systems are essential for handling the volume and velocity of RFID data. Specialized software for data ingestion and processing ensures that the data is cleansed, validated, and ready for analysis.

Philips and IBM’s partnership on RFID deployment is fascinating, especially considering the broader implications for supply chain management. It’s interesting to consider how this technology might be applied beyond simple inventory tracking, and I highly recommend checking out this insightful interview on the future of file sharing with Sharman Networks CTO Phil Morle beyond file sharing an interview with Sharman networks CTO Phil Morle.

Ultimately, the Philips/IBM partnership could lead to some exciting innovations in real-time tracking and data analysis, much like the advancements in file sharing the interview discusses.

Data is structured to support various querying and reporting functions, which will support the intended use cases. For example, a manufacturing environment may use RFID to track raw materials, in-process inventory, and finished goods, allowing real-time monitoring and management of the entire supply chain.

Data Security and Privacy Considerations

Data security and privacy are paramount in any system handling sensitive information. Implementing robust security protocols, including encryption and access controls, is crucial to protect data from unauthorized access or breaches. Data encryption ensures confidentiality during transmission and storage. Access controls define who can access what data, minimizing risks. Compliance with relevant data privacy regulations is also essential.

This includes adhering to regulations like GDPR, CCPA, or HIPAA, depending on the specific industry and geographic location. For instance, in healthcare, compliance with HIPAA is critical for protecting patient data.

Data Analytics for Decision-Making

Data analytics transforms raw RFID data into actionable insights. Sophisticated algorithms and statistical models can identify trends, anomalies, and patterns. Predictive modeling can forecast maintenance needs, optimize inventory levels, and anticipate potential disruptions. For example, by tracking equipment usage patterns, a facility can proactively schedule maintenance, minimizing downtime and maximizing equipment lifespan. Analyzing historical data on product movement allows for better forecasting of demand and optimized inventory management.

Dashboards for Real-Time Tracking and Monitoring

Real-time dashboards provide a clear view of the RFID-enabled assets. These visual tools display key metrics and performance indicators, enabling quick identification of issues or opportunities. Customizable dashboards allow users to focus on specific metrics relevant to their role or responsibility. Visualizations can highlight the location of assets, their current status, and any deviations from expected performance.

Philips and IBM’s partnership on RFID deployment is pretty cool, especially when you consider the potential for streamlining supply chains. Thinking ahead to the holidays, this kind of tech could be incredibly useful in managing inventory for retailers, making sure everything arrives on time. That’s why checking out some of the best tech gadgets for the holidays here is a great way to see the future of logistics in action.

Ultimately, the RFID integration with Philips’ products and services could revolutionize how we shop and receive items.

For instance, a retail store can track the location of products on the shelves and identify potential stockouts or slow-moving items, allowing for quick replenishment.

Real-Time Data Visualizations

Real-time data visualizations offer a compelling way to understand the value of RFID data. Interactive maps show the location of assets in real-time, enabling immediate responses to events or changes. Charts and graphs illustrate trends and patterns in asset usage, providing insights into operational efficiency. For example, a warehouse can visualize the movement of goods through the facility, enabling optimized routing and minimizing delays.

Histograms or heat maps can display the frequency of certain events or locations, providing valuable insight into areas requiring attention.

Market Trends and Future Outlook

The RFID industry is experiencing a period of significant growth and transformation, driven by advancements in technology and increasing adoption across diverse sectors. This evolution presents exciting opportunities for the Philips-IBM partnership, which can leverage these trends to further enhance their RFID deployment strategies. The convergence of data analytics and real-time tracking is a key driver, enabling unprecedented insights and operational efficiencies.The future of RFID is intertwined with the evolving needs of businesses seeking to optimize supply chains, enhance inventory management, and improve overall operational efficiency.

The increasing demand for real-time data and intelligent automation is pushing the boundaries of RFID technology, leading to more sophisticated and comprehensive applications.

Key Market Trends in the RFID Industry

The RFID market is experiencing several key trends that are reshaping its landscape. These trends are influencing the types of deployments, the technologies used, and the overall market dynamics.

- Increased Adoption in Healthcare: The use of RFID in healthcare is accelerating, driven by the need for improved patient safety, medication management, and streamlined hospital workflows. For example, RFID tags are being integrated into medical devices and equipment to enhance tracking and inventory control, ultimately improving patient care and reducing operational costs. This trend is a significant opportunity for the Philips-IBM partnership, given Philips’ extensive presence in the healthcare sector.

- Rise of IoT Integration: RFID technology is increasingly being integrated with the Internet of Things (IoT) to create more interconnected and intelligent systems. This integration allows for real-time data collection, analysis, and action, enabling predictive maintenance, proactive supply chain management, and enhanced security. This trend is particularly relevant for the Philips-IBM partnership, as it opens avenues for integrating RFID data with existing IoT platforms and systems.

- Focus on Data Analytics and AI: The value of RFID data is increasingly recognized, leading to a greater emphasis on data analytics and artificial intelligence (AI) to derive actionable insights. This trend enables businesses to optimize processes, predict future events, and make data-driven decisions, potentially improving efficiency and profitability. The Philips-IBM partnership can benefit significantly from the ability to leverage advanced analytics for more effective RFID deployment.

Potential Impact of the Partnership on the Broader Market

The collaboration between Philips and IBM has the potential to significantly impact the broader RFID market.

- Enhanced Technology: The partnership could result in the development of more robust and sophisticated RFID solutions, pushing the boundaries of current capabilities and opening new application possibilities. This could lead to the creation of more advanced and specialized RFID systems, enabling increased accuracy, reliability, and cost-effectiveness in various industries.

- Expanded Market Reach: The combined expertise of Philips and IBM in their respective sectors will enable them to reach a wider range of industries and customers, further driving market adoption of RFID technology. This expansion of market reach could lead to new applications and opportunities for both companies.

- Improved Standardization: The collaboration may facilitate the development of standardized RFID protocols and technologies, which can further streamline interoperability and data exchange between different systems and devices. This would reduce complexities and ensure seamless integration across various applications.

Future Developments and Innovations in RFID Technology, Philips ibm partner on rfid deployment

Several developments are expected in the future of RFID technology, promising even greater capabilities.

- Miniaturization and Cost Reduction: Continued miniaturization and cost reduction of RFID tags will make them even more accessible and versatile, enabling broader adoption across various applications. This trend can be observed in various industries, such as consumer electronics, where smaller, more affordable tags are increasingly integrated into products.

- Improved Accuracy and Reliability: Enhanced accuracy and reliability in RFID data collection and transmission will be crucial for critical applications, such as healthcare and logistics. Advancements in antenna technology and signal processing techniques will improve the reliability of RFID systems in challenging environments.

- Integration with Blockchain Technology: The integration of blockchain technology with RFID systems could enhance security and traceability in supply chains. This will ensure the integrity and transparency of data, allowing for more accurate and reliable tracking of goods and materials throughout the entire supply chain.

Potential Future Partnerships Between Philips and Other Companies

The Philips-IBM partnership could pave the way for future collaborations with other companies.

- Collaboration with Logistics Providers: Partnerships with leading logistics providers will enhance the ability to track goods across complex supply chains, optimizing delivery times and minimizing losses. This collaboration could enable the creation of highly efficient and reliable logistics networks.

- Collaboration with Retail Companies: Collaborations with retail companies could optimize inventory management, enhance customer experience, and improve supply chain efficiency. The integration of RFID technology into retail settings can improve tracking of products, reduce shrinkage, and enhance customer service.

Projected Growth and Impact on the Global Market

The Philips-IBM partnership is projected to drive significant growth and impact on the global RFID market.

- Increased Market Share: The collaboration will likely result in a significant increase in the market share for both Philips and IBM in the RFID sector. This will enhance their competitiveness in the market.

- Enhanced Industry Adoption: The advanced and reliable RFID solutions developed through this partnership will likely increase industry adoption, leading to broader application in diverse sectors. This trend is observed in industries where enhanced tracking and data collection have proven beneficial.

Case Studies and Examples

RFID technology is rapidly transforming various industries, and its impact on efficiency and profitability is undeniable. This section explores successful RFID deployments in similar sectors, showcasing the positive effects and providing insights into how Philips can leverage this technology for enhanced operational excellence. We’ll also delve into successful partnerships within the tech sector, offering valuable learning points for Philips and IBM’s collaboration.This section presents real-world examples of RFID deployment, demonstrating the potential benefits for Philips’ operations.

We’ll explore how these strategies translate into tangible improvements in supply chain management, inventory control, and asset tracking. Comparisons across different industries will highlight the versatility of RFID and its applicability to various operational contexts.

Successful RFID Deployments in Similar Industries

Real-world implementations demonstrate the effectiveness of RFID across industries. Companies like Walmart and several pharmaceutical distributors have implemented RFID to enhance their supply chain management. These deployments resulted in improved inventory accuracy, reduced loss and waste, and optimized logistics. This demonstrates a potential for significant improvements in Philips’ own operations.

- Pharmaceutical Distribution: Accurate tracking of pharmaceuticals is crucial for safety and compliance. RFID tags on drug containers allow for real-time tracking of temperature, location, and handling procedures, reducing the risk of product degradation and ensuring compliance with regulations. This is especially important for temperature-sensitive pharmaceuticals, which is a common practice in the pharmaceutical sector.

- Retail Sector: RFID technology has significantly improved inventory management in retail settings. By tagging products with RFID, retailers can accurately track inventory levels, optimize stock replenishment, and reduce theft. This can lead to improved sales and reduced operational costs.

- Manufacturing: RFID tracking of parts and equipment during manufacturing processes streamlines operations and reduces errors. The real-time visibility of assets enables proactive maintenance and scheduling, thereby minimizing downtime and improving overall productivity.

Positive Impact of RFID Implementation

The positive impact of RFID implementation extends beyond cost savings. It encompasses enhanced operational efficiency, improved safety, and greater customer satisfaction. For instance, real-time tracking of products enables proactive intervention to mitigate potential issues before they impact customers.

- Reduced Operational Costs: RFID systems reduce labor costs associated with manual inventory checks and minimize stockouts, thereby decreasing the costs associated with ordering replacements.

- Increased Efficiency: Real-time visibility of goods and assets improves efficiency across the entire supply chain, from manufacturing to delivery.

- Improved Accuracy: RFID’s accuracy in tracking assets reduces errors and ensures data integrity, enabling more reliable reporting and analysis.

RFID’s Potential for Philips’ Operations

Philips can leverage RFID in various areas to enhance its operations. RFID can streamline inventory management of medical devices and supplies, enabling accurate tracking of equipment across hospitals and clinics. Improved inventory management ensures timely delivery and reduces stockouts.

- Supply Chain Management: Tracking medical devices from manufacturing to end-users provides real-time visibility into the entire supply chain, enabling proactive measures to address potential delays or issues.

- Inventory Management: RFID tags on medical devices and supplies enable real-time inventory tracking, reducing stockouts and improving efficiency in managing and replenishing stock.

- Asset Tracking: Real-time tracking of medical equipment ensures its proper maintenance and availability, reducing downtime and improving service delivery.

Successful Partnerships in the Technology Sector

Collaboration between technology companies is critical for innovation and market penetration. IBM’s partnerships with other technology companies in the healthcare sector, including various pharmaceutical companies, demonstrate a commitment to advancing healthcare through technological innovation.

- IBM’s Healthcare Focus: IBM’s focus on healthcare partnerships underscores its commitment to developing innovative solutions for the sector.

- Collaborative Success: Successful collaborations demonstrate the value of joint efforts in developing and deploying cutting-edge technologies.

- Strategic Alliances: Strategic alliances between companies like Philips and IBM foster the development of innovative solutions for the healthcare industry.

Comparison of RFID Deployment Examples

Different industries demonstrate varying degrees of RFID adoption and application. While the pharmaceutical industry has adopted RFID extensively for temperature-sensitive drugs, other sectors are still exploring its potential. A detailed analysis reveals unique challenges and opportunities across different sectors.

| Industry | RFID Application | Impact |

|---|---|---|

| Pharmaceutical | Temperature monitoring, product tracking | Enhanced safety, improved compliance |

| Retail | Inventory management, theft prevention | Reduced costs, increased efficiency |

| Manufacturing | Equipment tracking, parts management | Reduced downtime, improved productivity |

Technical Specifications and Standards

The successful deployment of RFID systems hinges on meticulous adherence to technical specifications and standards. Understanding these ensures interoperability, security, and reliable data acquisition. This section delves into the crucial standards, tag and reader specifications, compatibility considerations, and security protocols integral to a robust RFID solution.

Relevant RFID Standards and Protocols

RFID deployments are governed by various standards, each impacting the tag, reader, and communication protocols. These standards ensure interoperability between different RFID systems and devices. The most prevalent standards include EPCglobal Class 1 Gen 2, ISO 18000-6C, and ISO 18000-6B. These standards define the communication protocols, frequency bands, and data formats used for RFID applications. Understanding these standards is vital for system design and implementation.

Technical Specifications of RFID Tags and Readers

The performance and functionality of RFID systems are directly related to the specifications of the tags and readers employed. Different applications necessitate various tag and reader specifications. For instance, high-volume tracking might demand tags with high read rates, whereas applications requiring long-range sensing would favor tags and readers operating in specific frequency bands. Tags vary in memory capacity, power consumption, and operating temperatures, while readers differ in their read range, data transfer rates, and processing power.

Compatibility of Different RFID Technologies

Compatibility between different RFID technologies is a critical consideration for seamless integration. For instance, EPCglobal Class 1 Gen 2 tags and readers often operate in the 860-960 MHz frequency band. However, other standards, such as ISO 18000-6C, might operate in a different frequency band, which can cause compatibility issues. Careful selection of compatible technologies and appropriate bridging solutions are vital to ensure data exchange between systems.

Choosing the right technology based on the desired read range, data volume, and the specific application context is crucial for a successful deployment.

Authentication Methods and Encryption Standards

Security is paramount in RFID deployments. Various authentication methods and encryption standards are employed to protect sensitive data. Methods like cryptographic keys and digital signatures provide robust security mechanisms. Common encryption standards used in RFID include AES (Advanced Encryption Standard), which is employed to encrypt data transmitted between tags and readers. Secure communication protocols and encryption algorithms are crucial for safeguarding the confidentiality, integrity, and availability of data.

Technical Specifications Table

| RFID Technology | Frequency Band (MHz) | Read Range (meters) | Application | Typical Use Cases |

|---|---|---|---|---|

| EPCglobal Class 1 Gen 2 | 860-960 | 0.5-10 | Inventory Management, Supply Chain Tracking | Retail, Manufacturing |

| ISO 18000-6B | 915 | 0.5-5 | Asset Tracking, Access Control | Logistics, Healthcare |

| ISO 18000-6C | 2.45 | 1-20 | High-Volume Tracking, Industrial Automation | Manufacturing, Warehousing |

This table provides a concise overview of different RFID technologies and their key characteristics. The choice of technology will depend on the specific requirements of the application, such as the desired read range, data transfer rate, and the operational environment.

End of Discussion: Philips Ibm Partner On Rfid Deployment

The Philips-IBM partnership on RFID deployment represents a significant advancement in the application of RFID technology. By combining their respective strengths, the companies are poised to reshape supply chain management, enhance operational efficiency, and drive significant value for stakeholders. The potential for improved data analytics and real-time tracking promises a new era of precision and responsiveness in diverse industries.

The future of RFID, and the market, is undoubtedly brighter with this strategic alliance.