Twilight of Barcodes, Dawn of RFID

Twilight of barcodes and the dawn of RFID sets the stage for this enthralling narrative, offering readers a glimpse into a revolutionary shift in inventory management. From the historical context of barcodes, their limitations, and the rise of RFID technology, this exploration unveils the transformation underway. We’ll delve into the fundamental principles of RFID, its advantages and disadvantages, and how it’s changing various industries, including retail, manufacturing, and healthcare.

The story also encompasses the technological advancements driving this transition, the potential future of inventory management, and illustrative case studies that highlight the real-world impact.

This journey traces the evolution from the familiar barcode to the cutting-edge RFID technology. The comparison will reveal the advantages of RFID in speed, accuracy, and cost-effectiveness, outlining the factors that are driving this industry-wide shift. Furthermore, the impact on supply chains and logistics will be examined, along with specific industry use cases and their challenges.

Historical Context of Barcodes

Barcodes, those seemingly simple stripes, have a rich history interwoven with the evolution of inventory management and automation. Their journey from a conceptual idea to a ubiquitous technology reveals a fascinating story of innovation and adaptation. From humble beginnings in the 1940s, barcodes have transformed industries, impacting everything from grocery stores to global supply chains.The initial concept of a visual representation of data to streamline processes was a response to the increasing need for efficiency in handling vast quantities of goods.

Early attempts focused on automating identification and tracking, moving away from manual methods that were slow, error-prone, and often impractical in growing businesses. The early adoption of barcodes was largely driven by the need for improved accuracy and speed in managing goods, particularly in environments where inventory levels were high.

Early Development and Motivations

Barcodes emerged from a desire to automate data entry and tracking in environments with large volumes of goods. Early methods of inventory management, relying heavily on manual processes like handwritten records and physical counts, were often plagued by inaccuracies and delays. These inefficiencies directly impacted businesses’ ability to manage stock, track shipments, and maintain accurate records. The need for a more streamlined and reliable system was paramount.

Key Milestones in Barcode Evolution

The development of barcodes wasn’t a sudden event; rather, it was a gradual process of refinement and improvement. The evolution of barcode technology can be observed through key milestones, each contributing to its increasing sophistication and wider adoption.

- 1940s: Initial Concepts Emerge. Early experiments with visual codes to automate data capture and inventory tracking started taking shape. While not yet fully developed or widely adopted, the groundwork was laid for future innovations.

- 1950s: Research and Prototyping. Researchers and engineers began to explore different visual encoding schemes, experimenting with various patterns and formats. Early prototypes focused on the underlying principles of representing data through visual patterns. Limited testing and pilot projects demonstrated the potential for automation but the technology was not ready for large-scale implementation.

- 1970s: The Universal Product Code (UPC) is Introduced. This pivotal moment marked a significant turning point in barcode technology. The standardized UPC system, designed for product identification, was adopted by retailers. This standardized format for encoding data led to a wider range of applications, laying the foundation for future expansion.

- 1980s: Barcode Applications Diversify. Barcodes expanded beyond retail, finding applications in manufacturing, logistics, and other sectors. This diversification demonstrated the versatility and utility of the technology, leading to increased adoption across different industries.

- 1990s and 2000s: Barcode Technology Maturation. Improvements in scanning technology, data encoding methods, and software integration made barcodes more efficient and reliable. The increasing integration of barcode systems with computer systems further improved their utility and impact. This era saw a surge in barcode usage across various industries.

Comparison to Earlier Inventory Methods

Earlier inventory management methods often relied on manual processes, leading to significant inefficiencies. Handwritten records and physical counts were prone to errors, making it difficult to maintain accurate stock levels. This manual approach also struggled to keep pace with growing businesses and increasing volumes of goods. Barcodes offered a significant improvement by automating the process of identifying and tracking items, leading to reduced errors and faster processing times.

Limitations of Barcodes and the Need for Alternatives

While barcodes revolutionized inventory management, they did have limitations. Scanning limitations, the need for direct line of sight, and the inability to handle complex data meant that there was a demand for more flexible and comprehensive systems. This led to the development of newer technologies like RFID, which could handle more data, work in various environments, and handle more complex data sets.

Barcode Evolution Timeline

| Year | Event | Description | Impact on Industry |

|---|---|---|---|

| 1949 | Early Experiments | Initial conceptualization and experimentation with visual encoding systems. | Laying the groundwork for future barcode development. |

| 1973 | UPC Introduction | The Universal Product Code (UPC) is standardized and implemented in grocery stores. | Retail industry experiences a significant shift towards automated inventory management. |

| 1980s | Barcode Expansion | Barcodes are adopted across various industries, including manufacturing and logistics. | Improved efficiency and accuracy in diverse sectors. |

| 2000s | Advanced Scanning Technologies | Increased use of laser and CCD scanners for enhanced accuracy and speed. | Enhanced barcode system performance and integration with computer systems. |

Introduction to RFID Technology

RFID, or Radio-Frequency Identification, is a wireless technology that uses radio waves to identify and track objects. It’s rapidly replacing barcodes in many applications, offering significant advantages in terms of speed, efficiency, and data richness. This technology uses electromagnetic fields to communicate with electronic tags, which store information and transmit it to a reader. The technology’s ability to track items without direct contact revolutionizes inventory management, security, and supply chain optimization.RFID systems consist of three main components: the RFID tag, the RFID reader, and the back-end system for data processing.

The RFID tag, a small chip embedded with a unique identifier, contains the data to be read. The reader, equipped with antennas, receives the signal from the tag and transmits it for processing. The back-end system interprets the received data and stores or displays it accordingly. This seamless integration of hardware and software enables real-time tracking and improved operational efficiency.

RFID Tag Types and Characteristics

Different types of RFID tags cater to various needs and applications. These tags differ in their size, functionality, and the amount of data they can store. Understanding the specific characteristics of each type is crucial for choosing the right technology for a given application.

- Passive RFID tags rely on the reader’s energy to operate. They are inexpensive and simple, making them ideal for low-cost applications like livestock tracking. Their range is limited by the reader’s power and the tag’s antenna efficiency.

- Semi-passive RFID tags incorporate a small battery to enhance their range and power the circuitry. This gives them a longer range compared to passive tags, suitable for tracking goods in warehouses or on assembly lines. They still rely on the reader for power, but their extended range allows for greater flexibility.

- Active RFID tags contain their own power source, typically a battery, and transmit signals over longer distances. This allows for real-time tracking and data collection in environments where passive tags would be inadequate, like in large-scale manufacturing or logistics. The battery life of active tags can be a consideration for long-term deployments, and the cost is usually higher.

Benefits of RFID over Barcodes

RFID technology surpasses barcode systems in numerous ways. It offers faster data capture, reduced human error, and the potential for real-time tracking, which is crucial in today’s fast-paced supply chains. The ability to track items without direct contact simplifies operations and minimizes the risk of damage to the tagged products.

- Real-time tracking allows for immediate identification and location of items, enabling proactive adjustments to the supply chain.

- Increased accuracy reduces errors associated with manual data entry and bar code scanning.

- Improved inventory management enables real-time stock monitoring, avoiding stockouts and overstocking.

- Enhanced security allows for tracking and monitoring of items to deter theft or loss.

- Greater data richness enables the collection of more detailed information about products, including their location, temperature, and handling conditions.

Advantages and Disadvantages of RFID Implementation

Implementing RFID systems offers significant advantages, but also presents some challenges. Careful consideration of both aspects is crucial for successful deployment.

The twilight of barcodes and the dawn of RFID technology is upon us, and it’s fascinating to see how these advancements impact various sectors. This evolution is evident in the ongoing investigation of the SoBig F worm, where the Feds nabbed a blaster suspect, continuing to track the writer, highlighting the importance of new technologies for digital forensics. Ultimately, the shift from barcodes to RFID systems will revolutionize inventory management and security in the future, mirroring the intricate tracking efforts in cases like feds nab blaster suspect continue tracking sobig f writer and beyond.

- Advantages: Enhanced operational efficiency, improved accuracy, and real-time visibility across the supply chain. RFID’s capability to handle a large volume of data is also beneficial.

- Disadvantages: Initial investment costs for hardware and system integration can be substantial. Ensuring data security and privacy are also critical considerations. Proper training and support are essential for effective use of the system.

RFID Tag Comparison Table

The following table summarizes the key characteristics of different RFID tag types:

| Tag Type | Functionality | Range | Applications |

|---|---|---|---|

| Passive | Simple, low-cost identification | Short to medium | Inventory tracking, asset management, livestock tracking |

| Semi-passive | Enhanced range, requires reader power | Medium to long | Warehouse management, manufacturing, retail |

| Active | Long range, self-powered | Long | Logistics, asset tracking, high-volume inventory |

Transitioning from Barcodes to RFID

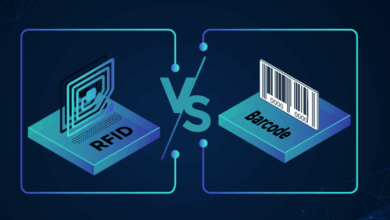

The relentless march of technological advancement has spurred a significant shift in inventory management and supply chain logistics. While barcodes revolutionized tracking, the limitations of this technology are increasingly apparent, paving the way for a more robust and versatile solution: Radio-Frequency Identification (RFID). This transition is not simply an upgrade; it’s a fundamental change in how we manage and monitor goods, leading to greater efficiency and accuracy.The primary impetus behind the transition from barcodes to RFID stems from the desire to overcome the inherent weaknesses of barcode technology.

Barcodes are essentially two-dimensional representations of data, susceptible to damage and prone to misreads, particularly in challenging environments. RFID, in contrast, provides a non-contact, more reliable method of tracking and identifying items, dramatically improving the efficiency and accuracy of supply chain operations.

Key Factors Driving the Shift

The inherent limitations of barcode technology are a primary driver of this shift. Barcodes require line-of-sight scanning, which can be problematic in cluttered environments or when items are stacked or moved frequently. RFID, with its ability to identify items remotely, overcomes these obstacles. Furthermore, the increasing complexity of supply chains necessitates a more comprehensive and adaptable tracking system.

RFID’s ability to track multiple items simultaneously and provide real-time data significantly enhances visibility and control. The cost-effectiveness of RFID over time also contributes to its adoption.

Challenges of the Transition

The transition from barcodes to RFID is not without its obstacles. Implementing RFID systems requires significant upfront investment in new hardware, software, and infrastructure. The migration process itself can be complex, involving data conversion, system integration, and training of personnel. Compatibility issues between different RFID systems can also pose a significant hurdle. Furthermore, privacy concerns associated with RFID data collection must be carefully considered and addressed.

Data security is crucial, as sensitive information is often embedded in RFID tags.

Industries Leading the Transition, Twilight of barcodes and the dawn of rfid

Several industries are leading the transition to RFID technology. The automotive industry, with its complex supply chains and the need for precise tracking of parts, is a prime example. Retailers are also embracing RFID for improved inventory management, reducing theft, and enhancing customer experience. The healthcare industry leverages RFID to track pharmaceuticals and medical equipment, ensuring patient safety and regulatory compliance.

The reasons for these transitions are multifaceted, encompassing improved inventory accuracy, enhanced supply chain visibility, reduced operational costs, and better compliance with regulations.

Potential Impacts on Supply Chains and Logistics

The adoption of RFID technology is expected to profoundly impact supply chains and logistics. Real-time visibility into inventory movement, enhanced tracking of goods throughout the supply chain, and improved traceability are all anticipated benefits. Furthermore, automated processes, reduced errors, and improved efficiency in various stages of the supply chain will become increasingly prevalent.

Barcode vs. RFID Comparison

| Feature | Barcode | RFID |

|---|---|---|

| Speed | Relatively slow; requires physical scanning | Fast; can track multiple items simultaneously |

| Accuracy | Prone to errors, especially in challenging environments | High accuracy; less susceptible to damage and environmental factors |

| Cost | Lower initial cost; lower ongoing cost for simple applications | Higher initial cost; lower ongoing cost in many cases due to efficiency gains |

RFID offers a significant leap forward in supply chain management, offering unparalleled capabilities for tracking and managing goods. Its advantages in speed, accuracy, and the ability to operate in challenging environments position it as a powerful tool for the future of logistics.

Impact on Different Industries: Twilight Of Barcodes And The Dawn Of Rfid

RFID technology is rapidly reshaping various sectors, offering unprecedented opportunities for enhanced efficiency, accuracy, and security. From streamlining supply chains to improving patient care, RFID’s potential is vast and multifaceted. This evolution builds upon the foundations of barcodes, leveraging advancements in wireless communication and data processing to unlock new possibilities.

Retail

RFID is revolutionizing retail operations by enabling real-time inventory tracking and reducing shrinkage. Automated tracking of products from the warehouse to the shelf allows for precise stock management, minimizing overstocking and lost sales. Retailers can gain a comprehensive understanding of customer preferences and purchasing patterns, leading to more targeted marketing campaigns. For instance, RFID tags on clothing can provide detailed information about the garment’s origin, material, and manufacturing process, potentially increasing consumer trust and satisfaction.

Furthermore, RFID-enabled checkout systems can significantly reduce wait times and enhance the overall customer experience. The potential for personalization and targeted promotions is substantial, creating more engaging and profitable shopping experiences.

Manufacturing

RFID tags can be integrated into manufacturing processes to track materials, parts, and finished goods. This allows for greater visibility into the entire production cycle, identifying bottlenecks and improving efficiency. Predictive maintenance based on real-time data gathered from RFID tags on machinery can prevent costly downtime and reduce operational expenses. For example, manufacturers can monitor the location and condition of critical components in real-time, enabling proactive maintenance scheduling.

This reduces unexpected breakdowns and ensures optimal performance.

Healthcare

RFID technology has significant applications in healthcare, improving patient safety and efficiency. RFID tags can be used to track medical equipment, pharmaceuticals, and even patients themselves. Real-time tracking of medication helps ensure proper storage and administration, minimizing errors and improving patient outcomes. For instance, implantable RFID tags can provide critical information about a patient’s medical history, allergies, and current medications, facilitating rapid response in emergency situations.

This proactive approach significantly reduces response times and improves patient safety.

The twilight of barcodes is giving way to the dawn of RFID, and this exciting shift is greatly aided by the recent FCC spectrum increase, which opens up more wireless room for the technology to grow. This boost in available wireless bandwidth, as detailed in the article fcc spectrum increase gives wireless room for the technology to grow , is paving the way for faster, more reliable, and more efficient RFID systems, potentially revolutionizing inventory management and beyond.

This increased wireless capacity is a crucial element in the overall evolution from barcodes to RFID, making the future of tracking and identification brighter.

Supply Chain Management

RFID’s impact on supply chains is profound, improving visibility and traceability across all stages. Real-time tracking of goods throughout the supply chain enhances inventory management, reduces delays, and minimizes errors. RFID tags provide accurate information about the location, condition, and movement of goods, enabling proactive management of potential issues and streamlining the overall process. From raw materials to finished products, RFID offers a comprehensive view of the supply chain, enabling businesses to make informed decisions based on real-time data.

| Industry | Use Cases | Benefits | Challenges |

|---|---|---|---|

| Retail | Inventory tracking, loss prevention, targeted marketing, personalized shopping | Reduced shrinkage, improved stock management, enhanced customer experience, optimized inventory | Initial investment costs, potential for data privacy concerns, system integration complexity |

| Manufacturing | Tracking materials, parts, and finished goods, predictive maintenance, optimizing production lines | Increased efficiency, reduced downtime, improved quality control, enhanced traceability | Complexity of integration with existing systems, potential for system failures, data security concerns |

| Healthcare | Tracking medical equipment, pharmaceuticals, patients, ensuring medication adherence | Improved patient safety, reduced medication errors, enhanced operational efficiency, improved workflow | Regulatory compliance issues, potential privacy concerns, high initial cost of implementation |

| Supply Chain Management | Real-time tracking of goods, improved visibility, enhanced traceability, reduced delays | Optimized logistics, reduced inventory costs, improved delivery times, increased efficiency | Integration challenges with existing systems, potential for data security breaches, need for skilled personnel |

Technological Advancements in RFID

RFID technology, once a niche area, is rapidly evolving, becoming more sophisticated and versatile. This evolution is driven by the need for greater efficiency, cost reduction, and enhanced security in diverse applications. The ongoing improvements in range, data capacity, and cost-effectiveness are making RFID a compelling alternative to traditional barcodes across various sectors.

Ongoing Advancements in RFID Technology

The quest for improved RFID technology is a multifaceted endeavor. Ongoing advancements encompass enhanced range, enabling wider application in more challenging environments. Improvements in data capacity allow for storing more information per tag, increasing the potential for richer data collection and analysis. Cost-effectiveness is also a key driver, with manufacturers striving to reduce the price of RFID tags and readers, thereby increasing the adoption rate and profitability of RFID solutions.

These improvements in RFID technology are pushing its boundaries beyond the initial implementations and opening up exciting new possibilities.

Emerging Trends in RFID Technology

Several emerging trends are shaping the future of RFID. One prominent trend is the increasing use of miniaturized RFID tags, which are becoming smaller and more integrated into various products. This miniaturization allows for more discreet implementation in diverse applications, from consumer goods to industrial machinery. Integration with other technologies, like IoT platforms, is also a significant trend, enabling real-time data collection and analysis.

Another crucial trend is the evolution towards longer-range RFID systems, which facilitates contactless interaction and eliminates the need for physical contact, enhancing operational efficiency and reducing potential risks.

Miniaturization and Integration in RFID

Miniaturization and integration play a crucial role in the advancements of RFID technology. Smaller tags are less obtrusive and easier to integrate into products, which is a major benefit for consumer products and asset tracking. This integration also opens doors for innovative applications like embedded RFID tags in clothing, enabling personalized tracking and management. Further miniaturization allows for higher density packing of tags, offering the possibility of monitoring large numbers of items simultaneously.

These integrated solutions increase efficiency and accuracy in various applications, reducing costs and enhancing operational efficiency.

Security Implications of RFID Technology

Security is a critical consideration in the deployment of RFID technology. The potential for unauthorized access to data stored in RFID tags necessitates the implementation of robust security measures. Encryption and authentication protocols are crucial for protecting sensitive information transmitted via RFID systems. Strict adherence to security best practices, including proper data handling and secure storage, is vital.

Implementing advanced encryption techniques and using authentication methods like biometric identification can mitigate security risks.

Key Improvements in RFID Technology Over Time

| Year | Key Improvement | Impact |

|---|---|---|

| Early 2000s | Increased range and data capacity of RFID tags | Enabled wider use cases, including tracking goods in supply chains |

| Mid 2010s | Miniaturization and integration of RFID tags | Enabled more discreet and widespread adoption in consumer goods |

| Present | Cost reduction and improved efficiency of RFID systems | Enhanced the accessibility of RFID technology to smaller businesses and industries |

| Future | Longer-range RFID and integration with IoT platforms | Facilitating contactless interaction and real-time data analysis |

The Future of Inventory Management

The shift from barcodes to RFID technology promises a profound transformation in inventory management and logistics. This evolution isn’t just about replacing one system with another; it’s about unlocking a wealth of data and efficiency gains that were previously unimaginable. The potential for real-time tracking, enhanced accuracy, and reduced operational costs is substantial, paving the way for a more agile and responsive supply chain.The future of inventory management hinges on RFID’s ability to provide detailed and real-time insights into product movement.

This capability will not only optimize stock levels but also enable proactive adjustments to demand fluctuations, leading to a significant reduction in waste and increased profitability. Moreover, the integration of data analytics with RFID systems promises a more holistic view of the entire supply chain, allowing businesses to anticipate potential bottlenecks and make informed decisions in real-time.

Potential Impact on Inventory Management and Logistics

RFID technology offers significant potential for streamlining inventory management and logistics. Real-time tracking of goods, from origin to destination, enables businesses to monitor stock levels, anticipate demand, and optimize delivery routes. This enhanced visibility allows for more efficient resource allocation and reduced operational costs. Predictive maintenance of equipment can also be improved, further reducing downtime and optimizing resource utilization.

The twilight of barcodes is giving way to the dawn of RFID, a fascinating shift in data management. This transition highlights the crucial need to upgrade and archive our existing data, especially as we move towards new technologies like RFID. Upgrade and archive the ongoing threat of data extinction is paramount to ensuring the reliability and value of this information in the face of this changing landscape.

Ultimately, the evolution from barcodes to RFID will only become more impactful as we proactively address the potential for data loss.

Future Scenarios for Inventory Management with RFID

| Scenario | Description | Impact |

|---|---|---|

| Proactive Inventory Management | RFID-enabled systems predict demand fluctuations, adjusting inventory levels dynamically. | Reduced stockouts and overstocking, minimizing waste and improving profitability. |

| Enhanced Supply Chain Visibility | Real-time tracking of goods through the entire supply chain, from manufacturing to delivery. | Improved responsiveness to market changes, enabling quicker adjustments and improved customer service. |

| Optimized Warehouse Operations | RFID-powered automated systems for picking, packing, and shipping, minimizing manual intervention. | Increased efficiency and accuracy in warehouse operations, leading to reduced labor costs and faster order fulfillment. |

| Improved Customer Service | Accurate real-time inventory information facilitates precise order fulfillment and improved delivery estimates. | Enhanced customer satisfaction through quicker delivery and more accurate order fulfillment. |

The Role of Data Analytics in the RFID Context

Data analytics plays a crucial role in unlocking the full potential of RFID systems. The vast amount of real-time data generated by RFID tags can be analyzed to identify trends, predict future demand, and optimize various aspects of inventory management. Sophisticated algorithms can uncover patterns in product movement, customer behavior, and supply chain dynamics, enabling businesses to make data-driven decisions and improve efficiency.

For example, analyzing RFID data on product location and movement within a warehouse can optimize picking routes and reduce order fulfillment times.

The Twilight of Barcodes and the Future of Retail and Logistics

The decline of barcodes will inevitably reshape retail and logistics. Businesses will need to adapt to the new capabilities and efficiencies offered by RFID systems. This transition will require significant investments in new infrastructure, software, and training. However, the long-term benefits, such as reduced costs, improved efficiency, and enhanced customer service, will ultimately outweigh the initial investment.

A shift towards a more data-driven approach in logistics and retail will be crucial, as companies will need to analyze the vast amount of data generated by RFID systems to make informed decisions and optimize their operations.

Illustrative Case Studies

RFID technology, while promising, needs concrete examples to demonstrate its real-world impact. Successful implementations in various industries highlight the potential for increased efficiency, transparency, and cost savings. These case studies provide a valuable insight into the practical applications of RFID and the challenges faced during the transition.Explaining the benefits of RFID often involves analyzing successful case studies, as they provide tangible evidence of the technology’s impact.

By examining the experiences of different companies, we can understand how RFID solutions have improved inventory management, supply chain visibility, and operational performance. These detailed accounts show not just the “what” but also the “how” and “why” behind successful RFID deployments.

Retail Sector: Improving Inventory Management and Customer Experience

Retailers face significant challenges in managing vast inventories across multiple locations. RFID offers a powerful solution for tracking products throughout the supply chain, from warehouse to store shelves.

- A major clothing retailer implemented RFID tags on their garments. This enabled real-time inventory tracking, allowing them to accurately predict demand and optimize stock levels. The system also identified slow-moving items, enabling proactive adjustments to inventory strategies and minimizing losses due to overstocking. The retailer experienced a 15% reduction in shrinkage and a 10% increase in sales due to better stock management and reduced out-of-stock situations.

This demonstrates how RFID improved inventory visibility and helped the company make more informed decisions.

- A grocery chain used RFID to track produce from farm to store. This enhanced traceability, allowing them to ensure freshness and quality control at each stage of the supply chain. By monitoring the temperature and handling conditions, they could identify potential quality issues early on, reducing waste and maintaining customer satisfaction. The chain experienced a 10% reduction in produce waste, which translated into significant cost savings.

Automotive Industry: Optimizing Parts Management and Supply Chain

The automotive industry relies heavily on complex supply chains. RFID solutions can significantly improve parts tracking and inventory management.

- A major automotive manufacturer used RFID tags to track parts in their assembly lines. This allowed for real-time visibility of part locations, facilitating efficient workflow and reducing delays. The system helped them minimize downtime by quickly locating needed parts, leading to a 12% reduction in assembly line delays and a 5% improvement in overall production efficiency. The manufacturer also improved their ability to respond to supply chain disruptions, demonstrating the resilience of RFID-enabled systems.

- An automotive parts supplier implemented RFID in their warehouse. This enabled accurate tracking of parts throughout the warehouse, allowing for improved inventory control and faster order fulfillment. The implementation resulted in a 15% reduction in order fulfillment time and a 20% reduction in labor costs associated with locating parts.

Logistics and Transportation: Enhancing Visibility and Efficiency

RFID plays a crucial role in improving the visibility and efficiency of logistics and transportation operations.

- A large shipping company used RFID tags on containers. This provided real-time tracking of shipments, allowing for accurate delivery estimations and improved customer communication. The system enabled better route optimization and reduced delivery delays. This resulted in a 10% reduction in delivery time and a 5% improvement in on-time delivery rates.

- A courier service utilized RFID to track packages throughout the delivery network. The system allowed them to monitor package location, temperature, and handling conditions, ensuring the timely and safe delivery of sensitive items. This increased customer trust and reduced the risk of loss or damage.

Summary of Case Studies

| Industry | Key Improvement | Measurable Benefit |

|---|---|---|

| Retail | Inventory management, shrinkage reduction, stock optimization | 15% reduction in shrinkage, 10% increase in sales |

| Automotive | Parts tracking, assembly line efficiency, supply chain resilience | 12% reduction in assembly line delays, 5% improvement in production efficiency |

| Logistics/Transportation | Shipment tracking, route optimization, delivery efficiency | 10% reduction in delivery time, 5% improvement in on-time delivery rates |

Wrap-Up

In conclusion, the twilight of barcodes and the dawn of RFID marks a significant turning point in inventory management. This transition, fueled by technological advancements and driven by the need for increased efficiency and accuracy, promises to reshape supply chains and logistics for the better. While challenges remain, the potential benefits across various industries are substantial, paving the way for a more streamlined and transparent future.

The shift from physical barcodes to digital RFID solutions represents a significant leap forward in inventory management, opening up exciting new possibilities for businesses.