IBM to Roll Out Integrated RFID Revolutionizing Industries

IBM to roll out integrated RFID, a groundbreaking new system poised to transform various industries. This innovative technology promises significant improvements in efficiency and visibility across supply chains and operations. Expect detailed insights into the potential benefits, technical aspects, market implications, implementation strategies, security considerations, and real-world use cases. IBM’s integrated RFID system will likely impact sectors like retail, manufacturing, and logistics, offering solutions to optimize processes and enhance overall performance.

The rollout is anticipated to bring significant advancements in tracking and managing goods and inventory, from raw materials to finished products. Expect detailed analyses of the potential market share gains and the competitive landscape surrounding this technology. This comprehensive overview will cover everything from the underlying technology to the potential societal impact of widespread RFID adoption.

IBM’s Integrated RFID Rollout: Revolutionizing Supply Chains

IBM is poised to revolutionize supply chain management with its integrated Radio-Frequency Identification (RFID) system. This innovative approach promises enhanced visibility, efficiency, and cost savings across various industries. The system will leverage the power of RFID technology to track and manage goods throughout the entire supply chain, from origin to final destination. This detailed overview explores the key features, benefits, and target sectors of IBM’s RFID initiative.

Potential Benefits and Use Cases

IBM’s integrated RFID system offers a wide range of benefits across diverse sectors. Real-time tracking of goods enables precise inventory management, minimizing stockouts and overstocking. Automated data collection reduces manual errors and improves accuracy. Improved visibility across the supply chain streamlines operations, facilitating faster response times to disruptions. The system also enhances security by providing a detailed audit trail of goods movement.

For example, in the pharmaceutical industry, precise tracking of medications can prevent counterfeiting and ensure the quality and safety of products.

Target Industries and Sectors

IBM’s integrated RFID system is designed for deployment across multiple industries. The system is expected to prove valuable in industries with complex supply chains, requiring high levels of visibility and control. These include, but are not limited to, manufacturing, retail, logistics, and healthcare. Furthermore, the system will cater to specific needs within each sector, such as optimizing warehouse operations in manufacturing or enhancing inventory management in retail.

Impact on the Market

The rollout of IBM’s integrated RFID system is expected to have a significant impact on the market. It will drive efficiency and productivity enhancements, leading to cost reductions and increased profitability for companies adopting the technology. This technology will also force competitors to adopt similar measures, ultimately raising the bar for supply chain management standards. The system’s ability to improve transparency and traceability will foster greater trust and confidence among stakeholders.

For instance, consumers may expect greater product authenticity and safety in the food industry.

Detailed Analysis of Target Sectors

This table Artikels the potential benefits, use cases, and anticipated market impact of IBM’s RFID rollout across various sectors.

| Sector | Benefit | Use Case | Expected Impact |

|---|---|---|---|

| Manufacturing | Improved inventory management, reduced stockouts, enhanced operational efficiency | Tracking raw materials, finished goods, and in-process inventory throughout the manufacturing process. | Increased productivity, reduced costs, and improved supply chain responsiveness. |

| Retail | Real-time inventory tracking, optimized stock replenishment, reduced shrinkage | Tracking inventory across retail stores, warehouses, and distribution centers. Providing real-time visibility of product location. | Improved inventory accuracy, reduced operational costs, and enhanced customer experience. |

| Logistics | Enhanced visibility of goods movement, optimized transportation routes, improved delivery times | Tracking goods throughout the transportation process, identifying bottlenecks, and optimizing routes. | Reduced transportation costs, faster delivery times, and improved supply chain resilience. |

| Healthcare | Improved medication tracking, enhanced patient safety, reduced counterfeiting | Tracking medications throughout the supply chain, ensuring authenticity and proper handling. Tracking patient medical equipment and supplies. | Enhanced patient safety, reduced medication errors, and increased trust in the healthcare system. |

Technical Aspects of the Integrated RFID System

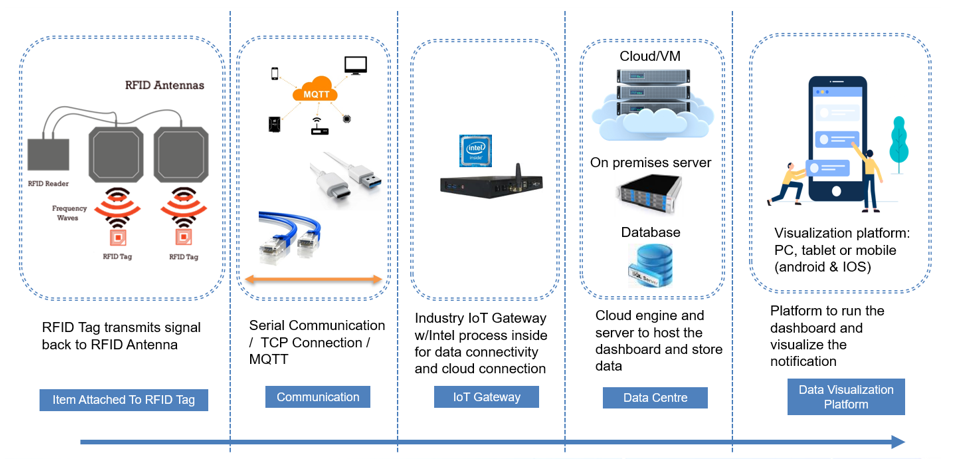

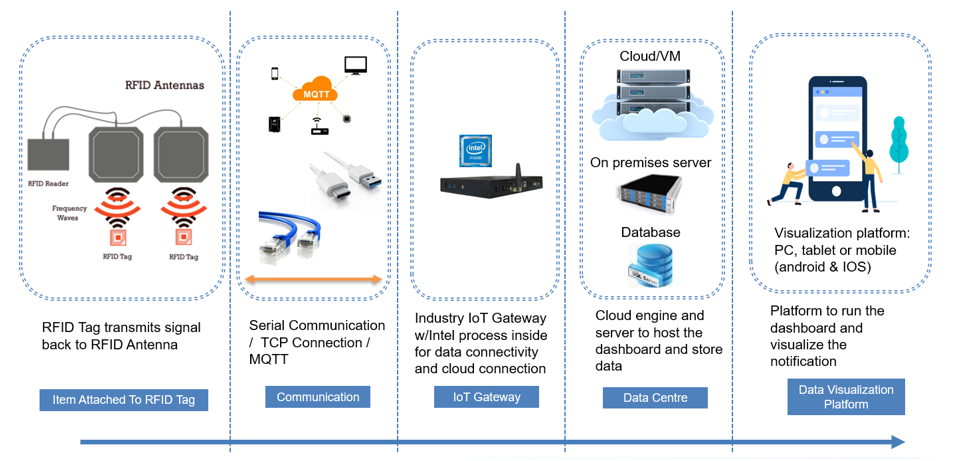

IBM’s integrated RFID rollout promises a significant leap forward in supply chain visibility and efficiency. This evolution hinges on a robust technical foundation, incorporating cutting-edge RFID technology seamlessly into existing infrastructure. This section dives into the core components, from the underlying chips to the data management strategies, to illustrate the technological underpinnings of this transformative initiative.The integrated RFID system leverages radio-frequency identification technology to track and monitor goods throughout the supply chain.

This real-time visibility, coupled with data analytics, allows for proactive decision-making, optimized inventory management, and improved responsiveness to market fluctuations. This innovative system is not just about tracking; it’s about gaining actionable insights to streamline operations and enhance profitability.

Underlying Technology, Ibm to roll out integrated rfid

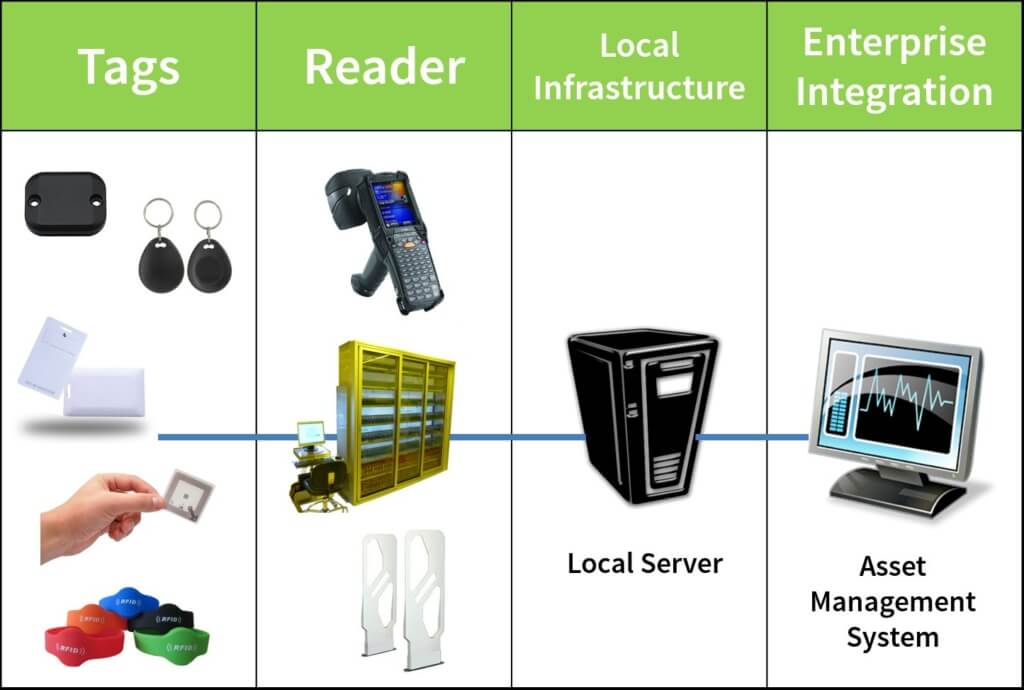

The technology behind IBM’s integrated RFID system relies on the principles of radio frequency communication. RFID tags, strategically placed on products, transmit unique identifiers to readers. These readers, in turn, communicate with a central system to collect and process the data. The system’s efficiency and accuracy are critically dependent on the precision of these radio frequency signals and the robust communication protocols employed.

RFID Chips and Tags

IBM’s system likely utilizes various RFID chip technologies, each with its own set of attributes. EPC Gen2, for example, is a widely adopted standard that provides extensive data storage capacity, enabling the encoding of detailed product information, such as manufacturing details, batch numbers, and expiry dates. Other types of RFID tags, tailored for specific applications within the supply chain, may also be incorporated.

These may include tags with enhanced read ranges, or specialized tags designed for harsh environments or specific materials. The choice of chip technology will depend on factors like the environment in which the tags will operate, the amount of data that needs to be stored, and the desired read range.

System Architecture and Design

The architecture of the integrated RFID system likely follows a distributed model, with readers strategically positioned at key points along the supply chain. This ensures that data is captured at various stages, from manufacturing to distribution and retail. The system’s design will need to incorporate robust security measures to protect the sensitive data transmitted, ensuring data integrity and preventing unauthorized access.

Scalability is a crucial element, allowing the system to accommodate future growth and expansion of the supply chain.

Data Processing and Management Strategies

Data processing is a critical component of the RFID system. Data collected from various readers is aggregated and processed by a centralized system. Sophisticated algorithms and data analytics tools are employed to extract insights and identify trends. This analysis can reveal bottlenecks in the supply chain, predict potential disruptions, and optimize inventory levels. Data security and compliance with industry regulations are also critical considerations, and the system will likely incorporate encryption and data masking techniques to ensure data confidentiality.

IBM’s upcoming integrated RFID rollout is pretty exciting. It’s a major step forward in efficiency, but what about the underlying processing power? Considering how AMD recently surpassed Apple’s G5 and Intel’s P4 in processing speed ( amd beats apples g5 and intels p4 ), it makes you wonder if IBM is leveraging this advanced technology in their new RFID systems.

This could potentially revolutionize how we track and manage inventory, leading to a whole new level of logistical prowess.

Comparison of RFID Technologies

| RFID Technology | Pros | Cons |

|---|---|---|

| EPC Gen2 | High data capacity, widely adopted standard, suitable for complex product information | Can be more expensive than other technologies, potentially higher power consumption |

| Low-Frequency (LF) | Cost-effective, good read range in some environments, suitable for certain materials | Limited data capacity, less accurate in diverse environments |

| High-Frequency (HF) | Relatively affordable, good read range, commonly used for asset tracking | Limited data capacity, less accurate in diverse environments |

| Ultra-High Frequency (UHF) | High data capacity, long read range, suitable for large-scale tracking, high accuracy | Potential interference in environments with high metal content, more expensive than some alternatives |

The table above provides a basic comparison of common RFID technologies. The specific technology employed by IBM will depend on the particular needs of the supply chain. Factors like the size and complexity of the inventory, the operating environment, and budget constraints will influence the optimal choice.

IBM’s upcoming integrated RFID rollout is definitely exciting, promising efficiency improvements across various industries. Interestingly, this mirrors a similar push towards innovation seen in the music industry, like how RealNetworks teamed up with Intel on a new music service, showcasing how technology is evolving across different sectors. This innovative approach to music streaming, detailed in realnetworks teams with intel on music service , suggests a broader trend in streamlining operations, and ultimately, the future of IBM’s RFID implementation will likely be equally impactful.

Market Implications and Competition

IBM’s integrated RFID rollout represents a significant step toward streamlining supply chains. Understanding the competitive landscape is crucial for assessing the potential impact and market share gains. This section delves into key competitors, their current offerings, and how IBM’s system compares. We’ll also explore potential market disruptions and growth projections.

IBM’s upcoming integrated RFID rollout is fascinating, especially considering the recent news about security concerns in application management. For example, microsoft talks application management security highlighting the importance of robust security measures. This likely means IBM’s RFID implementation will need to address these same vulnerabilities, ensuring data integrity and preventing potential breaches. The rollout itself should be interesting to see how they handle these security aspects.

Key Competitors and Their Offerings

Several companies are active in the RFID market, each with their own strengths and weaknesses. Major competitors include Zebra Technologies, whose focus on hardware and software solutions for retail and logistics is well-established. Other significant players are Honeywell, with a history in industrial automation and a robust presence in various sectors. These competitors often offer comprehensive solutions, including hardware, software, and services, tailored to specific industry needs.

The landscape is further diversified by smaller, specialized companies that target niche applications or emerging technologies.

Comparison of IBM’s System with Competitors

IBM’s integrated RFID system distinguishes itself through its focus on data integration and analytics. While competitors often offer strong hardware and software capabilities, IBM’s strength lies in connecting the RFID data with existing enterprise systems, fostering a holistic view of the supply chain. This integrated approach allows for real-time visibility and predictive analytics, a key differentiator. For example, IBM’s system could analyze real-time inventory levels, anticipate potential bottlenecks, and optimize logistics, surpassing traditional approaches focused solely on tracking.

Potential for Disruption and Innovation

The introduction of IBM’s integrated RFID system has the potential to disrupt the industry by pushing for greater data-driven decision-making in supply chain management. By integrating RFID data with other enterprise systems, companies can gain a level of real-time visibility and predictive capabilities not previously possible. This level of insight will encourage better inventory management, reduced waste, and improved overall efficiency.

For instance, a company using IBM’s system could forecast demand more accurately, leading to optimized production and reduced stockouts or overstocking.

Market Growth Projections and Anticipated Market Share Gains

The global RFID market is experiencing consistent growth, driven by the increasing need for real-time visibility and control over goods in transit. Predicting exact market share gains for IBM is challenging, but the company’s emphasis on integration and analytics could lead to significant market share gains. Factors like industry adoption rates, customer acceptance, and competitor responses will heavily influence the results.

However, the potential for increased efficiency and reduced costs associated with IBM’s integrated system presents a compelling case for growth. One example of this is the increased adoption of IoT technologies across various industries, which presents a fertile ground for RFID systems to flourish.

Key Features Comparison

| Feature | IBM’s Integrated RFID System | Zebra Technologies | Honeywell |

|---|---|---|---|

| Hardware | Robust, scalable, and integrated with IBM’s existing infrastructure | Wide range of RFID hardware for various applications | Extensive hardware portfolio, known for industrial applications |

| Software | Focus on data integration and analytics, connecting with existing ERP and CRM systems | Comprehensive software solutions for supply chain management and inventory control | Software solutions focused on automation and control in various industrial settings |

| Data Integration | Strong emphasis on connecting RFID data with enterprise systems for a holistic view of the supply chain | Good data integration capabilities, but IBM’s focus on enterprise-level connectivity may be a key differentiator | Focus on integration within their own ecosystem, but might require more custom integration for external systems |

| Analytics | Predictive analytics and real-time insights for optimized supply chain operations | Analytics capabilities are present but may not be as integrated as IBM’s | Analytics are often tied to their specific industrial automation solutions |

Implementation Strategies and Challenges

IBM’s integrated RFID rollout hinges on a meticulous implementation strategy. A phased approach, coupled with a robust deployment process, is crucial for a smooth transition and minimizing disruption to existing operations. Understanding potential challenges and proactively developing mitigation strategies are vital to ensure a successful and cost-effective deployment. This section details the planned implementation phases, deployment steps, and potential hurdles, providing a roadmap for a successful RFID integration.

Planned Implementation Phases

The RFID rollout will be implemented in a phased manner to minimize disruption and maximize operational efficiency. This phased approach allows for a gradual transition, enabling the company to learn and adapt to the system as it is deployed. Each phase will build upon the previous one, ensuring a smooth and well-integrated solution.

- Phase 1: Pilot Program and System Validation. This initial phase involves a select group of warehouses or distribution centers to serve as a testing ground. The pilot program allows for rigorous testing of the RFID system, ensuring its functionality and scalability. This step is crucial to identify any potential system limitations or operational inefficiencies. Key metrics, including data accuracy, throughput rates, and system downtime, are rigorously monitored during this stage.

- Phase 2: System Expansion and Training. This phase involves expanding the system to additional facilities and providing comprehensive training to personnel. The training will cover the system’s operation, maintenance, and troubleshooting. Detailed documentation and user manuals will be developed to support the training. Regular workshops and on-site support are critical to facilitate smooth integration.

- Phase 3: Full-Scale Implementation and Optimization. This final phase marks the complete rollout of the RFID system across all target facilities. This phase includes a review of the collected data to fine-tune system parameters and optimize processes. The system’s performance will be regularly monitored, and adjustments will be made as needed to ensure maximum efficiency.

Deployment Process Steps

A well-defined deployment process is essential for a successful RFID implementation. The process must be meticulously planned and executed, ensuring smooth integration with existing systems.

- Assessment and Planning. This initial step involves a thorough analysis of current warehouse processes, identification of RFID tags’ optimal locations, and selection of the most suitable RFID hardware and software solutions.

- Tagging and System Integration. This involves tagging products and integrating the RFID system with existing warehouse management systems (WMS). The correct placement of tags on products is essential for accurate tracking and efficient retrieval.

- Testing and Validation. Rigorous testing is necessary to validate the system’s accuracy and efficiency in real-world scenarios. Simulated operations and pilot programs are critical to identify and resolve potential issues.

- Training and Support. Comprehensive training programs are essential for all personnel involved in the RFID system’s operation and maintenance. Ongoing support and technical assistance should be available to address any issues that arise.

- Data Migration and Reporting. Migration of existing data into the new RFID system and the development of comprehensive reporting capabilities are crucial for the effective utilization of the system.

Potential Implementation Challenges and Mitigation Strategies

Several challenges may arise during the implementation process. Addressing these proactively is vital to ensure a successful outcome.

- High initial investment cost. The initial cost of RFID implementation can be substantial. Mitigation strategies include careful planning and phased implementation, focusing on areas with the highest return on investment first.

- Data accuracy issues. Inaccurate data collection can lead to inefficiencies and inaccuracies in inventory management. Mitigation includes meticulous data validation procedures and ongoing monitoring.

- System downtime. System downtime can cause significant disruptions. Mitigation strategies include redundancy in system components and proactive maintenance schedules.

- Resistance to change from staff. Resistance to change from personnel can hinder adoption. Mitigation strategies include comprehensive training programs, demonstrating the benefits of the system, and fostering open communication.

Step-by-Step Procedure for Implementation

A typical implementation scenario follows these steps:

- Assess current operations: Analyze existing workflows, identify bottlenecks, and areas for improvement.

- Select the right RFID system: Choose hardware and software that meet specific requirements and integrate seamlessly with existing systems.

- Develop a phased implementation plan: Create a detailed timeline with specific milestones for each phase.

- Tagging and system integration: Properly tag products and integrate the RFID system with existing warehouse management systems.

- Testing and validation: Conduct thorough testing to ensure data accuracy and system reliability.

- Staff training: Provide comprehensive training to all personnel involved in the RFID system.

- Monitoring and optimization: Continuously monitor the system’s performance and make adjustments as needed.

Implementation Timeline

| Phase | Key Milestones | Timeline |

|---|---|---|

| Phase 1: Pilot Program | System validation, data collection, initial training | Q1 2024 |

| Phase 2: System Expansion | Expansion to additional facilities, personnel training | Q2 2024 |

| Phase 3: Full Implementation | Full rollout, data analysis, system optimization | Q3 2024 |

Data Security and Privacy Considerations

RFID systems, while offering significant advantages for supply chain optimization, introduce new layers of complexity regarding data security and privacy. Protecting the sensitive information embedded within these systems is crucial to maintaining trust and preventing potential misuse. Careful consideration of security protocols, privacy implications, and best practices is paramount to a successful and ethical rollout.

Security Protocols for Data Transmission

Robust security protocols are essential to safeguard the integrity and confidentiality of data transmitted through RFID systems. Encryption techniques, such as AES (Advanced Encryption Standard), are commonly employed to scramble data during transmission, rendering it unreadable to unauthorized parties. Digital signatures, coupled with strong hashing algorithms, further authenticate the origin and integrity of the data, ensuring that it hasn’t been tampered with.

These cryptographic methods form the bedrock of secure data exchange.

Privacy Implications of RFID Technology

The pervasive nature of RFID technology raises significant privacy concerns. The constant tracking of goods and assets can potentially expose sensitive information about their movement and location. Careful consideration must be given to data minimization and anonymization techniques to mitigate these privacy risks. Implementing access controls to limit the visibility of data to authorized personnel is also crucial.

Best Practices for Data Security in RFID Systems

Implementing strong security measures involves more than just choosing the right encryption algorithms. Implementing access control policies that restrict data access to authorized personnel is paramount. Regular security audits, vulnerability assessments, and penetration testing are critical for identifying and patching potential weaknesses. Regular updates to the RFID system software and firmware are also vital to maintain the security of the system.

Potential Data Breaches and Their Prevention

Data breaches in RFID systems can have significant consequences, impacting both business operations and public trust. Potential breaches could arise from compromised RFID readers, malicious actors intercepting data during transmission, or vulnerabilities in the system’s software. To mitigate these risks, employing robust authentication mechanisms, secure network configurations, and regular security training for personnel is essential.

Security Measures, Vulnerabilities, and Mitigation Strategies

| Security Measure | Vulnerability | Mitigation Strategy |

|---|---|---|

| Strong Encryption (e.g., AES-256) | Weak encryption algorithms susceptible to brute-force attacks | Implement industry-standard encryption protocols and regularly update them to address new vulnerabilities. |

| Secure Data Transmission Protocols (e.g., HTTPS) | Data interception during transmission over insecure channels | Utilize secure protocols for all data exchanges and ensure strong network security measures. |

| Access Control Policies | Unauthorized access to sensitive data | Implement granular access control policies that restrict data visibility to only authorized personnel and limit access privileges. |

| Regular Security Audits | Unidentified vulnerabilities in the system | Conduct periodic security audits and vulnerability assessments to identify and address potential weaknesses in the RFID system. |

| Regular Firmware Updates | Exploitable vulnerabilities in outdated firmware | Maintain up-to-date firmware and software for all RFID components to ensure that known vulnerabilities are patched. |

Potential Use Cases in Different Sectors

IBM’s integrated RFID system promises a significant leap forward in supply chain management, offering unprecedented visibility and control across various sectors. This transformative technology, when implemented effectively, can streamline processes, reduce costs, and enhance customer satisfaction. The ability to track and trace goods in real-time is a game-changer, paving the way for optimized inventory management and improved operational efficiency.

Retail Sector

Real-time inventory tracking is a key benefit in retail. RFID tags on products allow retailers to monitor stock levels across stores and warehouses in real-time, minimizing stockouts and overstocking. This precision translates to reduced waste and optimized inventory management. Retailers can also leverage RFID to improve customer experience, enabling quicker checkout processes and providing personalized recommendations based on real-time product availability.

For example, a major clothing retailer used RFID to track inventory across its stores, leading to a 15% reduction in stockouts and a 10% increase in sales.

Manufacturing Sector

In manufacturing, the integrated RFID system facilitates efficient tracking of raw materials, components, and finished goods throughout the production process. This allows manufacturers to pinpoint bottlenecks, optimize production schedules, and reduce production delays. Real-time data visibility helps in quality control, as any discrepancies in the production process can be identified immediately. For instance, a car manufacturer utilized RFID to track parts during assembly, resulting in a 12% decrease in assembly time and a 5% improvement in product quality.

Logistics Sector

The logistics sector benefits greatly from RFID’s ability to track goods in transit. Real-time location information enhances route optimization, reducing delivery times and fuel consumption. Furthermore, the system facilitates the management of complex supply chains, enabling seamless coordination between suppliers, warehouses, and customers. An example of this is a large delivery company using RFID to track shipments in real-time, reducing delivery times by 10% and increasing customer satisfaction.

Table: Specific Use Cases by Sector

| Sector | Specific Use Case | Benefits |

|---|---|---|

| Retail | Real-time inventory tracking, improved customer experience, optimized stock management | Reduced stockouts, minimized waste, enhanced customer satisfaction, quicker checkout |

| Manufacturing | Tracking raw materials, components, and finished goods, optimized production schedules, improved quality control | Reduced production delays, increased efficiency, improved quality, identified bottlenecks |

| Logistics | Real-time location tracking, route optimization, management of complex supply chains | Reduced delivery times, optimized fuel consumption, improved supply chain coordination |

Economic and Societal Impacts

IBM’s integrated RFID rollout promises a transformative impact on supply chains, not just economically, but also socially and environmentally. This technology has the potential to streamline operations, enhance transparency, and foster a more sustainable future. The ripple effects will be felt across various sectors, from manufacturing and logistics to retail and healthcare. Understanding these potential impacts is crucial for a comprehensive evaluation of the RFID initiative.

Potential Economic Benefits

The implementation of RFID technology can yield substantial economic benefits. Improved inventory tracking and real-time visibility lead to reduced stockouts and overstocking, optimizing resource allocation and minimizing storage costs. This, in turn, directly impacts operational efficiency and reduces the risk of costly delays. Furthermore, enhanced supply chain visibility allows for better negotiation power with suppliers, enabling cost reductions.

The ability to accurately track products throughout the supply chain reduces the likelihood of theft and counterfeiting, safeguarding revenue streams. Real-world examples of successful RFID implementation in logistics demonstrate significant cost savings and improved efficiency.

Societal Implications of Widespread Adoption

Widespread RFID adoption will likely have profound societal impacts. Greater transparency in supply chains can foster trust and consumer confidence in the products they purchase. Consumers can gain insight into the origin and journey of products, enabling informed purchasing decisions. This heightened transparency can also support ethical sourcing initiatives and promote sustainable practices. The increased efficiency of supply chains can potentially lead to lower prices for consumers.

Furthermore, the data generated by RFID systems can be leveraged to improve product quality and customer service.

Employment Changes and Job Creation Opportunities

The integration of RFID technology will likely result in both job displacement and job creation. Some manual tasks related to inventory management and tracking may become automated, potentially leading to a reduction in certain roles. However, the implementation and maintenance of RFID systems will require skilled technicians and data analysts. New roles in data analysis, system management, and supply chain optimization are likely to emerge.

The specific impact will depend on the industry and the pace of implementation. For example, the shift from manual counting to automated tracking in warehouses might necessitate retraining for some employees, while new roles in data interpretation and analysis would be created.

Environmental Impacts

The environmental impact of RFID technology is generally positive. Reduced waste from overstocking and understocking can lead to less material consumption. Improved supply chain efficiency can minimize transportation costs and emissions, resulting in a lower carbon footprint. Furthermore, the ability to track products throughout their lifecycle allows for more sustainable practices to be implemented and monitored.

Economic Benefits, Societal Impacts, and Environmental Considerations

| Aspect | Economic Benefits | Societal Impacts | Environmental Considerations |

|---|---|---|---|

| Inventory Management | Reduced costs, improved efficiency, minimized waste | Increased transparency, consumer confidence, ethical sourcing support | Lower material consumption, reduced packaging waste |

| Supply Chain Visibility | Negotiation power improvement, reduced theft, fraud prevention | Informed consumer choices, enhanced traceability, improved customer service | Minimized transportation costs, lower emissions |

| Overall Impact | Increased profitability, improved competitiveness | Enhanced trust, consumer empowerment, sustainable practices | Reduced environmental footprint, sustainable supply chains |

Final Thoughts: Ibm To Roll Out Integrated Rfid

In conclusion, IBM’s integrated RFID rollout presents a compelling opportunity for industries to embrace innovative solutions for improved efficiency, security, and visibility. While challenges may arise during implementation, the potential benefits are substantial. This initiative promises to reshape the way goods are tracked and managed, offering significant opportunities for growth and optimization across various sectors. The future of supply chain management and logistics may well depend on this game-changing technology.