IBM Opens Customized Power Chips

IBM opens customizes power chips, ushering in a new era of tailored computing power. This innovative approach allows IBM to design chips optimized for specific tasks, a departure from the standard, one-size-fits-all approach. From AI to healthcare, the potential applications are vast, and the impact on various industries could be transformative.

The move to customize power chips signals a significant shift in the tech landscape. IBM’s history of pioneering custom chip design provides a strong foundation for this new initiative. The motivation behind this customization likely stems from a desire to outperform competitors and address the unique needs of demanding applications. This detailed look at IBM’s strategy will explore the technical intricacies, potential use cases, market impact, and future implications of this game-changing move.

Introduction to IBM’s Customized Power Chips

IBM’s foray into customizing its Power chips represents a significant shift in the semiconductor landscape. This approach allows for tailored hardware solutions, optimized for specific performance needs and functionalities, rather than relying solely on standardized designs. This strategy has implications for diverse industries, from high-performance computing to specialized AI applications. This customization strategy builds on IBM’s long history of innovation in chip design, aiming to address specific industry requirements and unlock new possibilities.This initiative signifies a departure from the typical mass-market approach to chip manufacturing.

Instead of producing a one-size-fits-all solution, IBM is leveraging its expertise to engineer processors that precisely meet the needs of individual clients and sectors. This approach promises enhanced performance and efficiency, potentially leading to breakthroughs in various fields.

IBM’s History in Custom Chip Design

IBM has a long-standing tradition of designing and manufacturing custom chips. This history demonstrates a commitment to tailored solutions and a deep understanding of specialized hardware requirements. The company’s involvement in custom chip design spans decades, reflecting its dedication to creating cutting-edge technologies for specific applications. From mainframe computers to specialized accelerators, IBM has always prioritized tailoring its hardware to meet particular demands.

IBM’s move to open-source and customize their power chips is pretty cool, isn’t it? It’s a fascinating development, and reminds me of a similar shift in the market a while back. Apple, for example, really shook things up with their low-cost G4 iBooks, a significant step in consumer electronics. apple ships low cost g4 ibooks Ultimately, these developments are making computer technology more accessible and innovative, pushing the boundaries of what’s possible with powerful chips, especially when customized for different needs.

IBM’s approach to customization looks like a smart way to compete in this dynamic landscape.

Motivations Behind Customizing Power Chips

IBM’s motivation for customizing its Power chips stems from several key factors. The primary driver is to meet the escalating demands of specific sectors, such as high-performance computing, AI, and data analytics. Tailoring chips to these needs can significantly enhance performance and efficiency, potentially yielding significant gains in processing speed and energy consumption. Moreover, customizing chips allows for the incorporation of specific architectural features, optimized for tasks such as complex calculations, image recognition, and machine learning.

Furthermore, IBM seeks to strengthen its position in niche markets by offering highly specialized hardware solutions.

Potential Benefits for Industries

Customizing Power chips offers numerous benefits across various industries. In high-performance computing, tailored chips can significantly boost processing speeds, enabling researchers and scientists to tackle complex simulations and datasets more efficiently. For AI applications, specialized chips can accelerate machine learning tasks, reducing training times and enabling faster development cycles. In data analytics, customized chips can optimize data processing, allowing for faster insights and more efficient data management.

This customized approach allows specific needs to be met and creates a competitive edge in each sector.

Types of Power Chips IBM Might Customize

The customization of IBM Power chips could encompass a variety of designs, each tailored to specific needs. These include:

- High-Performance Computing (HPC) chips: These chips are optimized for computationally intensive tasks, such as simulations and modeling, by emphasizing core count, memory bandwidth, and instruction-level parallelism.

- Artificial Intelligence (AI) accelerators: These chips are tailored for AI workloads, focusing on deep learning operations, neural network processing, and matrix multiplication. They are designed with specialized instructions and architectures to accelerate AI-related tasks.

- Data analytics chips: These chips are optimized for handling massive datasets, emphasizing data movement and manipulation. Specific optimizations for data compression, filtering, and aggregation are likely incorporated into these chips.

- Security chips: IBM might design specialized chips for cryptographic operations and secure data processing, incorporating enhanced security features and protections against attacks.

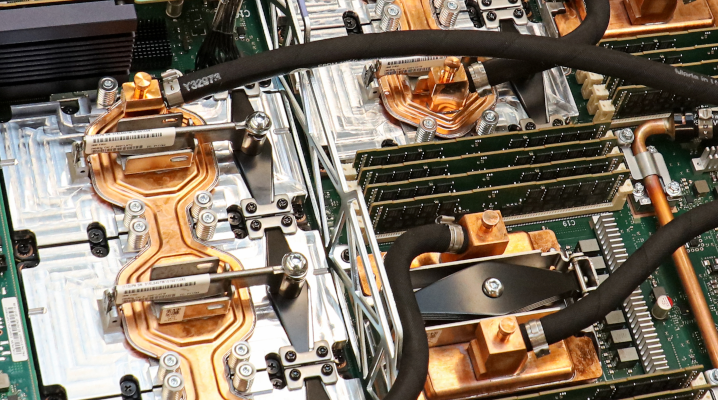

Technical Aspects of Customization

IBM’s foray into custom Power chips represents a significant advancement in processor design. Moving beyond standardized architectures, this approach allows for tailored solutions optimized for specific workloads. This opens doors to performance gains and power efficiency improvements unavailable with off-the-shelf chips. The intricate process of designing and manufacturing these custom chips involves a unique set of technologies and methodologies.The design process is complex, requiring extensive simulation and verification to ensure the customized architecture functions as intended.

This involves creating detailed models of the chip’s components and interactions, testing various scenarios to validate performance under different conditions. Manufacturing these chips often involves specialized processes, pushing the boundaries of semiconductor fabrication technology.

Specific Technologies Used in Customization

A multitude of technologies are employed in crafting custom Power chips. These include advanced design automation tools for circuit layout, sophisticated simulation software to predict chip behavior, and specialized fabrication techniques for achieving the desired characteristics. The precise combination of these technologies allows IBM to tailor the chip’s architecture to meet specific needs, a crucial step in the design process.

For example, customized logic gates, optimized transistor arrangements, and specific interconnect schemes are often incorporated to enhance performance.

Process of Designing and Manufacturing Custom Power Chips

The process of designing and manufacturing custom power chips is a multifaceted undertaking. It begins with defining the specific requirements of the target application. This involves analyzing the workload and identifying the critical performance bottlenecks. The design team then creates a tailored architecture that addresses these bottlenecks, carefully considering factors such as power consumption, performance, and area constraints. Following this, the design undergoes extensive simulation and verification to ensure its functionality.

Once the design is validated, the manufacturing process begins, often involving lithography, etching, and deposition techniques. The rigorous testing procedures at each stage guarantee the reliability of the final product.

Challenges in Custom Chip Design and Manufacturing

Designing and manufacturing custom chips presents several challenges. One significant hurdle is the substantial time and resource commitment. The intricate design process, combined with the need for specialized equipment and skilled personnel, can stretch timelines and budgets. Another significant challenge is the high degree of complexity. The sheer number of components and their intricate interactions can lead to unforeseen design flaws and manufacturing defects.

Maintaining high quality and reliability throughout the entire process is crucial to success.

Comparison with Standard Chip Production, Ibm opens customizes power chips

Standard chip production relies on pre-defined architectures and readily available components. Custom chip production, conversely, requires a complete redesign and fabrication process. The design process for custom chips is more complex and demanding, requiring substantial effort in simulation and verification to ensure proper functionality. The manufacturing process is also unique, tailored to the specific architecture of the custom chip.

Potential Areas of Outperformance

Custom chips have the potential to significantly outperform standard offerings in various areas. For example, they can be optimized for specific workloads, leading to improved performance and energy efficiency. This is especially valuable in applications with highly demanding requirements, such as high-performance computing or artificial intelligence. Custom chips can also be tailored to meet unique physical constraints of the target environment, such as limited space or power.

This adaptability is crucial in applications where size and power consumption are critical, like embedded systems.

Applications and Use Cases

IBM’s customized Power chips represent a significant advancement in chip design, enabling tailored solutions for diverse applications. This customization allows for optimized performance and energy efficiency, crucial for tackling complex computational tasks across various sectors. The potential impact on industries like AI, healthcare, and finance is substantial, promising enhanced capabilities and improved decision-making processes.

Potential Applications Across Industries

These customized chips are not a one-size-fits-all solution; their value lies in their adaptability. Their ability to be tailored to specific needs makes them highly attractive for a range of applications, particularly those demanding significant processing power or specialized algorithms.

AI Applications

AI algorithms, especially deep learning models, require massive computational resources. Customized Power chips can significantly accelerate training and inference processes, enabling faster and more accurate predictions. For instance, in image recognition tasks, a customized chip optimized for convolutional neural networks (CNNs) could dramatically reduce the time needed to analyze vast datasets, opening doors to faster and more reliable AI-powered solutions in fields like autonomous driving and medical diagnosis.

The ability to adapt the chip architecture to specific AI models leads to superior performance and efficiency.

Healthcare Applications

In healthcare, customized chips can support the development of sophisticated diagnostic tools and personalized treatment plans. The analysis of medical images, for instance, can be accelerated with specialized chips optimized for image processing. This leads to faster diagnoses and potentially more effective treatments. Furthermore, personalized drug discovery processes can benefit from custom chips, facilitating the development of tailored therapies for specific patient profiles.

This would reduce development time and cost, leading to faster introduction of novel therapies.

Finance Applications

Financial institutions rely on complex algorithms for risk assessment, fraud detection, and algorithmic trading. Customized chips can provide the high-performance computing capabilities required to execute these complex computations in real-time, ensuring faster and more accurate decisions. This translates to enhanced security, reduced risk, and improved trading strategies. For example, a chip optimized for financial modeling could process vast datasets much more quickly than standard processors, enabling quicker and more informed investment decisions.

Performance Comparison: Custom vs. Standard Chips

| Use Case | Custom Chip Performance (Estimated) | Standard Chip Performance | Key Advantages of Custom Chips |

|---|---|---|---|

| AI Image Recognition (CNN) | 10x faster inference | 1x | Optimized architecture for CNNs |

| Medical Image Analysis (Segmentation) | 5x faster processing | 1x | Specialized hardware acceleration for image processing |

| Financial Modeling (Risk Assessment) | 2x faster computation | 1x | Optimized architecture for financial algorithms |

Note: Performance figures are estimates and may vary based on specific chip design and implementation.

Market Impact and Competitive Analysis

IBM’s foray into custom Power chips represents a significant strategic shift, potentially reshaping the landscape of high-performance computing. The company’s ability to tailor these chips to specific customer needs suggests a move toward greater market segmentation and potentially higher margins. This customization approach contrasts with the more standardized offerings often found in the industry.The potential market impact hinges on several factors, including customer adoption rates, the effectiveness of IBM’s marketing strategy, and the competitive response.

Will these chips be able to deliver compelling performance advantages over existing solutions? How will the customization process affect pricing and delivery times? These questions will be crucial in determining the success of this initiative.

Potential Market Impact

The market impact of IBM’s custom chips depends heavily on their ability to address specific niche demands. If these chips can offer unique performance advantages for particular workloads, they could gain significant traction in sectors like artificial intelligence, scientific research, and high-frequency trading. Such specialized solutions could allow IBM to command premium pricing. The chips’ ability to handle increasingly complex tasks and evolving technological requirements will be crucial.

Successfully meeting the demands of specialized computing tasks will directly influence the adoption rate.

Competitive Analysis

The competitive landscape for custom power chips is fierce. Existing players, including AMD and Nvidia, are already involved in the development of high-performance chips. Their extensive research and development investments, coupled with established customer bases, create significant hurdles for IBM. The company will need to differentiate itself by offering unique features, competitive pricing, and exceptional support. Successful market penetration will necessitate a strategic understanding of the competition’s strengths and weaknesses.

Comparison with Competitors

| Feature | IBM Custom Power Chips | AMD Custom Chips | Nvidia Custom Chips ||—————–|————————|——————-|——————–|| Specialization | High, tailored to specific needs | Medium, broader range of applications | High, focusing on AI and GPUs || Performance | Highly competitive, potentially leading in specific areas | Competitive, strong in certain workloads | Exceptional in AI/GPU acceleration, but may be less optimized for other workloads || Customization | Highly customizable, potentially creating significant cost advantages for large projects | Customizable, but may be less flexible than IBM’s approach | Highly customizable for specific AI workloads || Pricing | Premium, potentially adjusted based on customer needs | Competitive, varied based on application | Competitive, with premium for specific features || Ecosystem Support| Depends on IBM’s ecosystem development | Strong, with extensive developer tools and support | Strong, especially in AI/GPU computing |

Potential Risks and Opportunities

Developing custom chips is a complex undertaking. High development costs, lengthy production cycles, and unpredictable customer demand pose significant risks. IBM will need to effectively manage these challenges. Opportunities lie in leveraging the company’s extensive industry experience to build strong partnerships with key customers and in addressing specific performance needs that competitors are unable to fulfill. The company’s ability to effectively manage these risks will play a crucial role in the long-term success of this initiative.

Market Share Implications

The introduction of IBM’s custom power chips could potentially affect the market share of existing companies. If these chips gain traction in specific markets, they could attract customers away from competitors’ offerings. Conversely, if competitors successfully respond with comparable or superior solutions, IBM’s market share gains might be limited. This competitive dynamic will determine the long-term implications for IBM’s market share.

Future Implications and Trends

IBM’s foray into custom Power chips signifies a significant shift in the computing landscape. This approach, moving beyond standardized designs, promises to unlock unprecedented performance and efficiency, potentially reshaping the future of various industries. The ability to tailor chips to specific needs, rather than relying on generic architectures, suggests a powerful trajectory for innovation.

Future Directions for Custom Power Chips

IBM’s custom chips will likely evolve towards greater specialization. This means designing chips optimized for particular tasks or applications, rather than aiming for general-purpose use. Examples include chips focused on AI inference, high-performance computing (HPC), or specialized data processing for financial modeling. The development of these highly targeted solutions will likely accelerate the adoption of AI and other demanding technologies.

Emerging Trends Impacting Chip Design

Several trends will influence the design of these custom chips. The increasing demand for artificial intelligence (AI) is a major driver, pushing the need for specialized hardware capable of handling complex neural network computations. Furthermore, the relentless pursuit of quantum computing will demand specialized hardware for qubit control and manipulation. This will necessitate innovative chip architectures optimized for quantum algorithms.

Potential Scenarios for Long-Term Evolution

One potential scenario involves the emergence of a new generation of hybrid processors. These processors might combine custom Power chips with specialized accelerators for specific tasks, such as AI or machine learning. This approach could significantly improve overall system performance and efficiency. Another scenario involves the development of custom chips optimized for edge computing. This would allow for real-time data processing at the source, minimizing latency and bandwidth requirements.

Impact on the Future of Computing

The customization approach will profoundly shape the future of computing. It could lead to a paradigm shift from general-purpose computing to specialized hardware tailored to specific tasks. This trend will accelerate innovation in AI, HPC, and other computationally intensive fields. Furthermore, it could enable new applications and services that were previously unimaginable.

Potential for New Technological Breakthroughs

The development of custom Power chips could pave the way for new technological breakthroughs. The ability to tailor chip designs to specific needs could lead to advancements in energy efficiency, performance, and security. For example, custom chips optimized for medical imaging could provide faster and more accurate diagnostics. In the realm of data analytics, these chips could handle enormous datasets more effectively, enabling faster insights and decision-making.

IBM’s move to open-source and customize its powerful chips is a significant development, potentially disrupting the tech landscape. This innovation, however, doesn’t overshadow the ongoing legal battles facing Microsoft, who are again in court over an aging antitrust case, highlighting the complex interplay between tech giants and regulatory scrutiny. Ultimately, IBM’s customization approach could lead to exciting new possibilities for tailored hardware solutions.

Illustrative Examples of Customized Chips: Ibm Opens Customizes Power Chips

Customizing power chips for specific tasks, like AI processing, is becoming increasingly important. This approach allows for optimized performance and efficiency, often surpassing the capabilities of generic processors. The following example illustrates a hypothetical custom power chip designed for AI workloads.

Hypothetical AI Processing Chip

This hypothetical chip, codenamed “Synapse,” is designed specifically for accelerating deep learning algorithms. Unlike standard CPUs or GPUs, Synapse leverages a novel architecture focused on parallel data processing and optimized memory access. This specialization enables significant performance gains compared to general-purpose processors.

Architectural Differences from Standard Chips

Synapse departs from standard chip designs in several key areas. Its core architecture is based on a massively parallel neural network structure. Specialized hardware units handle matrix multiplication and activation functions, critical for deep learning computations. Furthermore, the chip incorporates a high-bandwidth on-chip interconnect to facilitate rapid data transfer between processing units, reducing latency and improving overall performance.

IBM’s move to open-source and customize its power chips is a fascinating development. It’s a bold step, but considering the recent backlash from US states regarding the Microsoft settlement, us states cry foul over microsoft settlement , it’s intriguing to see how this new wave of chip customization will play out. Ultimately, IBM’s approach to opening up its power chip design could lead to some serious innovation and competition in the tech sector.

Advantages and Disadvantages of Custom Design

Custom chips, while offering potential for substantial performance gains, present unique challenges. The advantages include tailored performance for specific applications, leading to reduced power consumption and higher throughput. However, designing and manufacturing custom chips involves significant upfront costs and development time. Furthermore, the specialized nature of the chip may limit its versatility and reusability in other applications.

The potential for obsolescence is another consideration if the target application or technology shifts rapidly.

Specifications and Features

| Specification | Feature |

|---|---|

| Processing Cores | 1024 specialized AI processing units |

| Memory Bandwidth | 200 GB/s |

| Interconnect | High-speed, on-chip network |

| Power Consumption | 100 Watts |

| Clock Speed | 1.5 GHz |

| Instruction Set | Optimized for deep learning algorithms |

Potential Applications

This specialized AI chip, Synapse, holds significant potential in various domains. It could power advanced image recognition systems in autonomous vehicles, enabling real-time analysis of complex visual data. In healthcare, it could accelerate drug discovery processes by rapidly analyzing vast datasets of molecular structures. Financial institutions could leverage it for fraud detection and risk assessment, processing massive transaction data with unparalleled speed and accuracy.

Finally, it could enable new breakthroughs in scientific research, allowing researchers to process and analyze complex scientific data at an unprecedented scale.

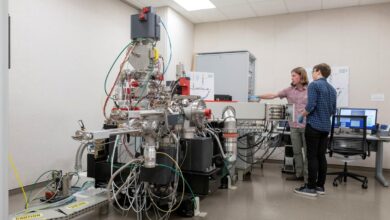

Visual Representation of the Process

Creating a customized Power chip at IBM involves a meticulous and intricate process, demanding specialized expertise and sophisticated tools. This process is not simply about adding or subtracting features; it’s about designing a completely tailored solution to meet specific performance and functionality requirements. Understanding the steps involved is crucial for grasping the complexity and precision needed to deliver these highly-engineered products.

Defining the Specification

This initial stage is critical, as it lays the foundation for the entire customization process. It entails a detailed analysis of the client’s needs and requirements. This involves careful consideration of the target application, performance benchmarks, power consumption constraints, and other specific parameters. Clear communication between IBM engineers and clients is essential to ensure a shared understanding of the desired outcome.

The outcome of this stage is a comprehensive specification document that acts as a blueprint for the subsequent steps.

Architectural Design

This stage focuses on creating a high-level blueprint for the chip’s architecture. Engineers use advanced design tools to map out the various components, their interconnections, and their functionalities. This stage considers the trade-offs between performance, power consumption, and area on the silicon die. The output is a detailed architectural design document that serves as a guide for the subsequent design stages.

Detailed Design and Simulation

The detailed design stage refines the architectural blueprint into a precise layout. This includes defining the specific transistors, interconnects, and other components. Extensive simulations are conducted to validate the design’s functionality and performance under various conditions. The outcome is a detailed design that is thoroughly verified and optimized before moving to the next step.

Fabrication and Testing

This stage involves the actual creation of the customized chip using advanced fabrication techniques. The design is transferred to a silicon wafer, and the chip is manufactured. Rigorous testing is performed at each stage to ensure that the chip meets the specifications Artikeld in the initial requirements document. The output of this stage is a functional, tested customized chip.

Verification and Validation

This step is crucial to confirm that the chip functions as intended and meets the performance targets defined in the initial specifications. This includes a comprehensive set of tests and analyses, encompassing a variety of scenarios and environmental conditions. Rigorous quality control procedures are essential to ensure the customized chip’s reliability and performance. The outcome is a validated and certified chip ready for integration into the intended application.

Customization Process Visual Representation

- Defining the Specification: Clearly articulating the client’s needs and requirements for the chip, establishing benchmarks, and ensuring a shared understanding of the desired outcomes.

- Architectural Design: Creating a high-level blueprint of the chip’s components, interconnections, and functionalities, considering performance, power consumption, and area constraints.

- Detailed Design and Simulation: Refining the architectural blueprint into a precise layout, defining components, and performing simulations to validate functionality and performance.

- Fabrication and Testing: Manufacturing the customized chip on a silicon wafer and rigorously testing it at each stage to ensure it meets specifications.

- Verification and Validation: Validating the chip’s functionality, performance, and reliability under various conditions and scenarios.

Final Summary

IBM’s foray into custom power chips promises a future where computing power is tailored to specific needs. The technical hurdles and potential market disruption are significant, but the potential benefits for industries like AI and healthcare are undeniable. This initiative could lead to new performance benchmarks and redefine the possibilities of computing. Only time will tell the full extent of IBM’s impact on the industry.