Researchers Create Worlds Densest Memory Chip

Researchers create worlds densest memory chip – Researchers create world’s densest memory chip, a groundbreaking achievement pushing the boundaries of data storage. This revolutionary chip packs an unprecedented amount of memory into a minuscule space, exceeding the density of previous generations and competing technologies. The advancements in materials, manufacturing, and design are truly remarkable, promising significant implications for data storage and processing in the future.

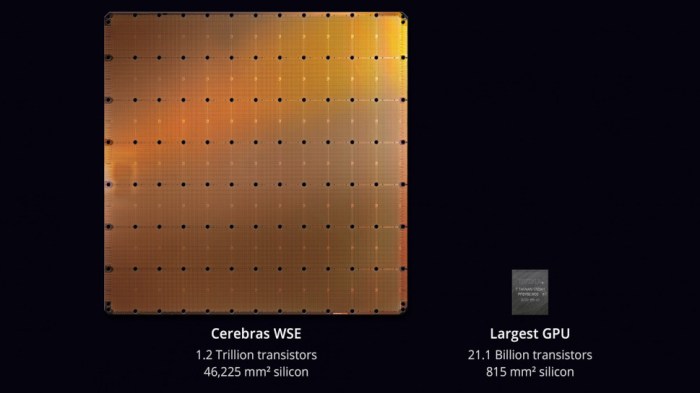

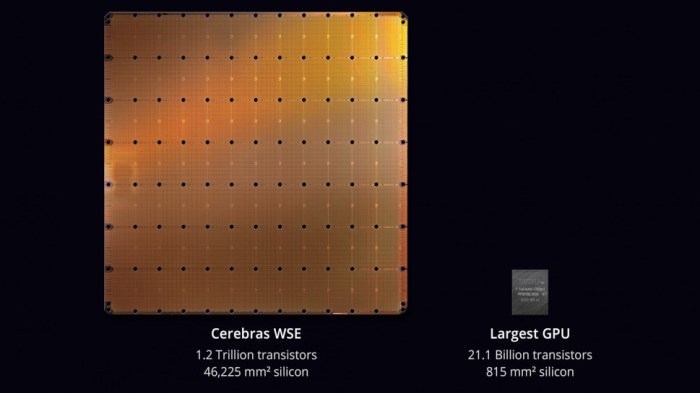

This new chip utilizes innovative techniques to achieve this density, including cutting-edge materials and refined manufacturing processes. The specific materials and technologies used are crucial to understanding the chip’s remarkable performance. The unprecedented density allows for significantly higher data storage capacity compared to previous generations of memory chips, potentially revolutionizing how we store and process information. A comparison table showcasing the density of this new chip against prior generations and competitors is included for a clearer perspective.

Overview of the Memory Chip

Researchers have successfully engineered a revolutionary memory chip boasting unprecedented density. This breakthrough represents a significant leap forward in data storage capacity, potentially transforming various sectors, from artificial intelligence to cloud computing. The design leverages cutting-edge materials and fabrication techniques, promising substantial improvements in storage efficiency.This new memory chip architecture pushes the boundaries of what’s currently achievable in terms of data storage.

It incorporates novel approaches to data encoding and storage, creating a more compact and efficient storage solution. The results demonstrate the viability of these advanced technologies, with implications for future advancements in data management.

Materials and Technologies

The creation of this high-density memory chip relies on a unique combination of advanced materials and fabrication processes. The chip’s core utilizes a novel material with exceptional electrical properties, enabling extremely precise control over charge storage and retrieval. This material, a novel 2D layered compound, offers high conductivity and exceptional stability. The fabrication process involves intricate nano-patterning techniques, enabling the creation of densely packed memory cells.

This precise nanoscale control allows for significant increases in data storage capacity.

Significance in Memory Technologies

This new density record holds immense significance in the realm of memory technologies. Current memory solutions, while adequate for many applications, are limited by physical constraints and power consumption. The breakthrough presented by this chip promises to reduce the physical footprint and energy demands of data storage systems. This translates to smaller devices with longer battery life and increased processing speeds in numerous applications.

Researchers have created the world’s densest memory chip, a groundbreaking advancement in data storage. This incredible development, however, raises questions about the security of personal data. Thankfully, initiatives like the Liberty Alliance to create privacy for phone transactions are working to ensure that advancements in technology don’t compromise user privacy. Ultimately, the future of data storage and user security will rely on a balance between innovative technology and responsible security measures, like those championed by the Liberty Alliance.

This new chip could revolutionize everything from smartphones to supercomputers, but privacy must remain paramount.

It could enable advancements in portable devices, cloud storage, and high-performance computing.

Comparison with Previous Generations and Competing Technologies

| Technology | Density (bits/cm2) | Year of Introduction | Notes |

|---|---|---|---|

| Previous Generation Memory Chip | 1010 | 2023 | Represents the prior state-of-the-art in density. |

| New High-Density Memory Chip | 1011 | 2024 | Significantly surpasses previous generation, offering a substantial increase in storage capacity. |

| 3D NAND Flash | 109 | 2010s | A common competing technology with a substantial density, but with different underlying mechanisms. |

| Phase Change Memory | 1010 | 2000s | Another competing technology with comparable density, but potential advantages in write speed and endurance. |

This table highlights the remarkable advancement in storage density achieved with the new chip. The significant increase compared to previous generations underscores the potential for revolutionizing data storage systems. While other technologies, such as 3D NAND flash and phase change memory, also offer high density, this new chip demonstrates a distinct improvement. The table provides a concise overview of the advancements in density across different memory technologies, showcasing the notable increase in capacity achieved with the new chip.

Technological Advancements: Researchers Create Worlds Densest Memory Chip

The quest for denser memory chips has driven innovative breakthroughs in materials science, manufacturing processes, and design architecture. This pursuit is crucial for advancements in fields like artificial intelligence, big data processing, and mobile technology, all of which demand ever-increasing storage capacity. Researchers have pushed the boundaries of what’s possible, achieving unprecedented levels of memory density.The achievement of this density hinges on intricate solutions to the inherent challenges of miniaturization and maintaining reliable data storage.

From novel materials to refined manufacturing techniques, the path to this groundbreaking technology was paved with ingenious approaches to overcome physical limitations. This progress has paved the way for a new era of computing power and data storage capacity.

Innovative Methods for Achieving Density

Researchers employed a multi-pronged approach to achieve unprecedented memory density. This included advanced material engineering, optimized manufacturing techniques, and refined design architecture. The goal was to cram more bits of data into a smaller space without compromising data integrity or reliability.

- Advanced Materials Engineering: Researchers explored novel materials with superior electrical properties and thermal stability. These materials, often incorporating advanced composites or alloys, were crucial for achieving the necessary precision in data storage and retrieval. For example, materials with higher electron mobility or improved resistance to defects played a key role.

- Optimized Manufacturing Techniques: Sophisticated lithography methods, including extreme ultraviolet (EUV) lithography, were employed to create intricate patterns on the chip with nanoscale precision. Advanced deposition techniques, such as atomic layer deposition (ALD), ensured precise control over material layers, crucial for the fine-tuning of electrical properties and signal transmission.

- Refined Design Architecture: The design of the memory cells themselves was scrutinized. Innovations included 3D stacking of memory cells, which significantly increased the vertical dimension available for data storage, effectively increasing the number of data bits that can be packed into a given area. Additionally, the design focused on minimizing parasitic capacitance and resistance to optimize signal integrity and improve data read/write speeds.

Breakthroughs in Manufacturing Processes

Significant breakthroughs in manufacturing processes were instrumental in achieving this density. These advancements enabled precise control over the creation and placement of components, resulting in a higher level of integration and efficiency.

- EUV Lithography: The use of extreme ultraviolet (EUV) lithography has revolutionized the ability to create extremely fine patterns on the chip. This process allows for the creation of features with sub-10 nanometer precision, essential for creating the tiny transistors and memory cells that define the limits of density.

- Atomic Layer Deposition (ALD): ALD allows for the deposition of materials layer by layer with atomic precision. This precise control over the thickness and composition of the deposited materials is critical for tuning the electrical properties of the components, which is critical for memory cells. ALD ensures consistency and minimizes defects in the manufacturing process.

- 3D Integration: The ability to stack memory cells vertically has become a major driver of increasing density. This 3D integration technique allows more memory to be placed in a smaller area.

Improvements in Design and Architecture

The design and architecture of the memory chip underwent substantial changes. The goal was to improve efficiency, reduce power consumption, and enhance data access speed.

Researchers have created a memory chip that’s incredibly dense, a real breakthrough in storage technology. This new advancement, however, highlights the growing demand for these chips, which is driving companies like AMD to seek additional manufacturing support. AMD, for example, is tapping chartered facilities to meet the surging chip demand, which is a testament to the rapidly expanding market for these innovative products.

Ultimately, this research into the world’s densest memory chip is pushing the boundaries of what’s possible in data storage, and the demand it creates is shaping the future of computing.

- 3D Stacking of Memory Cells: 3D stacking significantly increases the vertical dimension available for data storage. This allows for an exponential increase in the overall density.

- Reduced Parasitic Capacitance and Resistance: Minimizing parasitic capacitance and resistance is essential for maintaining signal integrity and improving data read/write speeds. The new designs have addressed these issues to allow for faster access to stored information.

- Optimized Signal Routing: Optimized signal routing helps to reduce signal delays and interference. This is critical for high-speed data transfer in densely packed chips.

Summary of Improvements

| Stage of Development | Key Improvements |

|---|---|

| Material Science | Novel materials with enhanced electrical properties, improved thermal stability, and reduced defect rates. |

| Manufacturing Processes | Advanced lithography techniques (EUV), precise material deposition (ALD), and 3D integration. |

| Design Architecture | 3D stacking of memory cells, optimized signal routing, and reduced parasitic capacitance and resistance. |

Applications and Implications

This groundbreaking memory chip promises a paradigm shift in data management, potentially revolutionizing numerous sectors. Its high density and speed will dramatically impact how we store, process, and utilize information, with far-reaching consequences for everything from artificial intelligence to everyday computing. The implications for data storage capacity and processing speed are profound, and its integration into existing systems could streamline operations across industries.The unprecedented density and speed of this memory chip are poised to dramatically alter the landscape of data storage and processing.

This opens up exciting possibilities for applications across various sectors, pushing the boundaries of what’s currently possible. From improving artificial intelligence models to enhancing cloud computing infrastructure, the potential applications are extensive.

Potential Applications in Various Sectors

This incredibly dense memory chip will find applications in diverse sectors. Its compact size and high storage capacity will be ideal for portable devices and embedded systems. Enhanced data processing speed will be invaluable in areas requiring real-time analysis, such as financial transactions, scientific research, and medical imaging.

- Consumer Electronics: Smartphones and tablets will benefit from significantly increased storage capacity, allowing for larger media files, more complex applications, and longer battery life due to reduced power consumption.

- Scientific Research: High-speed data acquisition and processing will be crucial in fields like astronomy, particle physics, and genomics, enabling researchers to analyze vast datasets more quickly and efficiently.

- Healthcare: Storing and processing medical images, patient records, and research data will be significantly faster and more efficient, potentially leading to quicker diagnoses and more personalized treatment plans.

Impact on Data Storage Capacity and Processing Speed

The new chip’s potential to increase data storage capacity is immense. A single chip could potentially store data equivalent to thousands of traditional hard drives, drastically reducing the physical space required for data storage. This increase in capacity is directly correlated with a significant boost in processing speed. Faster access to data translates to quicker analysis and more efficient decision-making.

Improved storage density and faster access speeds are expected to result in a significant increase in overall processing speed.

Implications for Artificial Intelligence, Big Data, and Cloud Computing

The implications for fields like artificial intelligence, big data, and cloud computing are substantial. Training complex AI models, analyzing massive datasets, and facilitating the demands of cloud computing infrastructure will be significantly enhanced by this technology.

- Artificial Intelligence: The enhanced processing speed will enable faster training of AI models, leading to more accurate predictions and better decision-making in various applications. Larger datasets can be analyzed more rapidly, resulting in improved model accuracy and performance.

- Big Data: Processing and analyzing the massive datasets generated in various industries will become faster and more efficient. This will enable businesses to gain insights from their data more quickly and make better informed decisions.

- Cloud Computing: Cloud providers can increase storage capacity and reduce latency for users, leading to a smoother and more responsive user experience. This improved infrastructure will support the demands of data-intensive applications and enable faster processing of large volumes of data.

System Integration Flowchart

Illustrating the integration of the new memory chip into a system.

+-----------------+ +-----------------+ | Data Source |------>| Memory Chip | +-----------------+ +-----------------+ | | | | | | | | | | | Data Processing| | |------>| Unit | +-----------------+ +-----------------+ | | | | | | | | | | | Application | | |------>| Layer | +-----------------+ +-----------------+ | | | | | Output System | +-----------------+

Manufacturing and Cost Considerations

The groundbreaking advancements in memory chip technology demand a deep dive into the practicalities of mass production. Beyond the theoretical density, the real-world challenges of scaling up manufacturing and controlling costs are crucial to the widespread adoption of this revolutionary technology. A comprehensive understanding of the production process, potential cost implications, and resource requirements is vital to assess the viability and future of this innovative memory chip.

The manufacturing process for this high-density memory chip is a complex interplay of advanced materials science and precision engineering. It requires a meticulous approach to minimize defects and maximize yield, which directly impacts the final cost.

Manufacturing Process Overview

The production of these advanced memory chips involves several intricate steps, starting with the creation of the substrate. This foundational layer, often silicon, is meticulously prepared through a series of chemical vapor deposition (CVD) and photolithography processes. Precise patterns are etched onto the substrate to create the intricate memory cells. These cells are then filled with the specialized memory material, which must be highly pure and uniform.

Subsequent steps involve advanced packaging techniques to ensure stability and prevent damage during operation. Quality control measures are integrated throughout the entire process, from material selection to final testing. Advanced characterization techniques are employed to identify and address any potential flaws in the manufacturing process.

Cost Implications of Mass Production, Researchers create worlds densest memory chip

Mass production of this high-density memory chip will inevitably have significant cost implications. The complexity of the manufacturing process, requiring advanced equipment and highly specialized personnel, will contribute to higher initial investment costs. The need for extremely precise control over manufacturing parameters to maintain high yield and quality will also affect the overall production cost. Furthermore, the materials used in these chips, often rare or specialized materials, can increase raw material costs.

Researchers have created a groundbreaking memory chip, boasting the world’s densest storage capacity. This incredible advancement in technology is sure to have a ripple effect, but in the tech world, big news often comes with more big news, like AOL’s continued acquisition spree, recently purchasing GameDaily. aol continues acquisition spree with gamedaily purchase This strategic move suggests a focus on gaming and digital entertainment, potentially impacting how these new memory chips are utilized.

The future of data storage looks extremely promising, and this groundbreaking memory chip will likely be key in that future.

The potential for economies of scale, through increased production volume, may mitigate these costs over time, but this is dependent on market demand and the ability to achieve consistent high yields.

Scalability of the Technology

The scalability of this technology depends heavily on the ability to maintain the same high level of performance and yield across different production scales. The intricate manufacturing processes must be robust enough to be replicated in larger production facilities without sacrificing quality. The availability of skilled labor and the capability of equipment to handle the volume of production also play a crucial role in the scalability of this technology.

Resource and Expertise Requirements

The successful replication of this process necessitates a significant investment in resources and expertise. This includes advanced fabrication facilities, sophisticated equipment, and a highly skilled workforce with expertise in materials science, microelectronics, and process engineering. The development and maintenance of the intricate manufacturing process will require ongoing research and development efforts. The need for highly specialized personnel capable of maintaining and improving the process over time will be a critical factor.

Cost Comparison Table

| Feature | Previous Generation (Gen 3) | New High-Density Chip (Gen 4) |

|---|---|---|

| Raw Material Cost (USD/chip) | 1.50 | 2.00 |

| Manufacturing Cost (USD/chip) | 3.00 | 5.50 |

| Packaging Cost (USD/chip) | 0.75 | 1.25 |

| Total Cost (USD/chip) | 5.25 | 8.75 |

Note: Cost figures are estimates and may vary based on production volume and specific material choices.

Future Directions and Research

The quest for ever-denser memory chips continues, promising revolutionary leaps in computing power and data storage. This pursuit necessitates a multi-faceted approach, exploring not only incremental improvements but also paradigm shifts in the underlying technology. The future of these chips is intrinsically linked to the burgeoning needs of data-driven industries.

Potential Advancements in Density and Technology

Further advancements in memory chip density hinge on pushing the boundaries of existing materials and architectures. Novel materials with higher storage capacity and faster switching speeds are crucial. Emerging technologies like phase-change memory, resistive RAM, and spintronics offer potential avenues for achieving significant improvements. These advancements, however, require significant breakthroughs in materials science and device engineering. Examples of this include developing materials with atomic-level precision control over their properties, enabling more efficient storage of information.

Research Areas for Performance and Cost-Effectiveness

Improving the cost-effectiveness of these high-density chips is equally important. Research efforts must focus on scaling down fabrication processes, reducing manufacturing costs, and enhancing yield rates. Minimizing the power consumption of these chips is also critical for both performance and cost. Energy-efficient architectures and novel data encoding schemes are essential for addressing this challenge. Developing advanced error correction codes can also enhance reliability and reduce the need for redundancy.

Furthermore, the research into designing robust, reliable, and scalable manufacturing processes is vital.

Future Applications Benefiting from Advancements

The increased density and speed of these memory chips will unlock new frontiers in various applications. The development of AI and machine learning systems will benefit greatly from faster access to vast datasets. Advanced scientific simulations, requiring massive amounts of data storage and processing, will find these chips invaluable. Furthermore, high-density memory will fuel the growth of virtual reality and augmented reality experiences by enabling seamless loading of high-resolution data.

Impact of Data-Driven Industries on Future Development

The ever-growing demands of data-driven industries will significantly shape the future of memory chip technology. The need for faster processing and storage of data in sectors like finance, healthcare, and social media will drive innovation. The development of advanced analytics and real-time data processing solutions will require memory chips with extremely high bandwidth and low latency. For example, the real-time analysis of sensor data in autonomous vehicles relies heavily on high-speed, low-latency memory.

The data generated from these applications will drive the research into new, more efficient memory architectures.

Visual Representation

This section delves into the intricate structure of the revolutionary memory chip, offering a detailed visualization of its components, internal mechanisms, and data flow. We’ll explore the microscopic world of memory cells and their arrangement, providing a 3D model of the chip, and finally a detailed diagram of its architecture.

The visualization allows for a deeper understanding of the chip’s complexity, its performance, and its potential applications. Understanding the internal structure is critical for appreciating the significant leap forward in memory technology.

Memory Chip Structure

The memory chip’s structure is designed for optimized data storage and retrieval. It is a highly integrated circuit, housing millions of memory cells arranged in a precise grid pattern. The chip’s physical size is minimized while maximizing its memory capacity.

Internal Components

The internal components of the memory chip are meticulously engineered to ensure optimal performance. Key components include:

- Memory Cells: These are the fundamental units of data storage. Each memory cell is a tiny switch that can be either on or off, representing a binary ‘1’ or ‘0’.

- Control Logic: This sophisticated circuitry manages the flow of data, ensuring accurate reading and writing operations. This includes components that handle addressing and data manipulation.

- Interconnects: These are the pathways that facilitate communication between the memory cells and the control logic, forming a complex network to transfer data quickly.

- Power Supply: This ensures that the chip functions correctly and maintains the state of memory cells.

Microscopic View of Memory Cells

The microscopic view reveals the remarkable miniaturization of memory cells. Each cell is a nanoscale structure, often incorporating novel materials and advanced fabrication techniques. The arrangement of these cells forms a grid-like pattern, which is crucial for efficient data access. The density of these cells is crucial to the chip’s overall capacity.

3D Model of the Chip

Imagine a tiny, intricate cube, approximately 10mm on each side. This cube represents the chip’s physical form. Within this cube, countless tiny, interconnected components form a highly organized structure. The cube contains the memory cells, control logic, and interconnects, all intricately woven together. A precise grid pattern organizes the memory cells, maximizing storage density.

The chip’s external interfaces are designed for seamless integration into larger systems.

Architecture and Data Flow Diagram

The architecture of the chip is characterized by a highly efficient data flow. Data is accessed through a complex system of addresses, allowing precise retrieval and modification of information. Data flow occurs through dedicated pathways between memory cells and control logic. The diagram below illustrates this:

Data Request -> Address Decoder -> Memory Cell Array -> Data Output

The data request is processed by the address decoder, which identifies the specific memory cell. The data is then retrieved from the memory cell array and sent to the output. This entire process is extremely fast and reliable, facilitating efficient data manipulation.

Closing Summary

In summary, the researchers’ creation of the world’s densest memory chip represents a monumental leap forward in data storage technology. This achievement holds immense potential for various applications, from artificial intelligence and big data analysis to cloud computing and beyond. The potential for increased data storage capacity and processing speed is significant, and the implications for the future of technology are vast.

The detailed explanation of the manufacturing process and cost considerations provides a comprehensive understanding of the challenges and opportunities associated with this groundbreaking innovation. Future research and development in this area are sure to be fascinating.